I'm thinking of having a stainless steel dynamo body made for my own use..Is anyone else interested in having one if the price is sensible? Originals were dull nickel plated and the stainless would look very similar.(for ever)..I think I'm down to my last two really good original dynamo bodies that are fit for plating...These days most are too rusted to come up well...Ian

email (option): ian@wright52.plus.com

Hi Ian

An interesting one that, but just asking - could use of stainless Steel affect its magnetic flux field - just wondering ?

Jo'b

email (option): Jonnyob1@googlemail.com

Another option may be to machine a bit off the diameter and press on some thin stainless tubing as they used to do with the old iron head Harley Sportsters, just a thought!

email (option): davmax@ntlworld.com

Yes i would like one off those stainles jobs Ian

email (option): evandeweerthof@yahoo.com

Hi John...I don't think it will have any effect on the dynamos operation..It's just steel with a little chromium and a few other elements added...

Dave...Worth looking at for sure...I could use up all those rusty bodies I have!...I'll have to check the dimensions..Ian

email (option): ian@wright52.plus.com

Are you proposing to replace the iron body with stainless? If so it wont work. You need the iron body for the residual magnetism.

Chris

email (option): chris@mgowner.co.uk

I understood the soft iron core of the windings provides sufficient residual magnetism for initial power generation, a portion of which is then fed back into the field coil. This then generates a sufficiently strong magnetic field to produce the higher current required to power the system. The dynamo body plays no part in this process as far as I am aware...Even if it did a 400 grade 'magnetic' stainless steel would be an option....Ian

email (option): ian@wright52.plus.com

Its just an idea but the dynamo body may act as a "keeper" for the residual magnetism in the iron core. If so there may be a problem with the dynamo not working if the bike is left for a long time. The magnetic stainless may be the way to go.

P.S. Don't forget you'll have to engrave all the writing that's on the bodies!

Sorry but Chris has it right.

If you are going to do a stainless body then you will need to machine it from a ferritic grade ( magnetic ) of "stainless"

Bike Beesa

Trevor

Who may or may not have beeen a metallurgist in a former existance

email (option): wariron@tpg.com.au

I can find no reference to the dynamo body being used to provide residual magnetism...Everything I have read implies it is the iron core of the armature and the pole shoe of the field coil that provide this function...

Can you point me in the direction of some information to confirm what you are suggesting? (that the dynamo body provides residual the magnetism)...Ian

email (option): ian@wright52.plus.com

Can you point me in the direction of some information to confirm what you are suggesting? (that the dynamo body provides residual the magnetism)...Ian

BSA Service sheet 809 under "Field Coil" and I quote

" the latter (pole shoe expander) being especially necessary to ensure that there will not be any airgap between the pole shoe and the inner face of the yoke"

This means that there must be a magnetic path between these two parts

I'm an engineer and work with aircraft electric motors, starters, generators, and other electromechanical equipment.

Many brushmotors for elecrtrical have stainless components, often of what most people call 'nonmagnetic' stainless grades- steels that aren't attracted to magnets. Stainless steels do not have a high 'permanance' but do have high 'permability.' Most people only think of permanance when they think of whether a metal is magnetic. That's not the only measure of magnetic properties. Stainless will pass a magnetic field (permeable), but won't retain one (has low permanance) after the source of the magnetic field is removed (the field current is cut off by the regulator). Another issue is the geometry of the dyanmo. The field winding core will have a much greater effect on retaining the magnetic field than the body of the dynamo, becuase the field winding core's flux lines are concentrated in the area where they perform work.

My opinion: it won't make any difference if its made of stainless vs. soft steel. Furthermore, if you're really worried, you could make the body of a grade of stainless that has a lot of permanence.

My moneys with Trevor and Chris!

Seriously tho is it realy worth all the trouble, whats wrong with getting it plated and now and then giving it a wipe with WD40 to stop it rusting.

You can try a dull version of this:

http://vwparts.aircooled.net/Stainless-Steel-12V-Generator-Cover-p/3511.htm

Noam.

email (option): noam10@gmail.com

I think the field windings iron core is whats doing the work in terms of residual magnetism...L.A. Kevins practical experience appears to confirm that, or at least that it is not the body...

It is far more likely to my mind that the iron core (a material generally used for magnets) is more likely to be performing this role than the far less suitable (welded) steel body....

I think the lack of air gap behind the pole shoe is more about the very limited clearance between that part and the (rotating)armature than it is about creating a magnetic field...I guess I'll prove the theory one way or another when I make the first one and fit it....Ian

email (option): ian@wright52.plus.com

It's good thread this Ian,

My original comments weren't related to residual magnetism within the body - more to do with permitting lines of magnetic flux etc. - ferrous v stainless steel

On the ac electrical stuff I have dealt with in the past, laminated sections of ferrous materials are used in order to help direct lines of flux and to disapate heat more quickly - you see this in more modern style ignition coils

A st steel body is still of interest to me though !!

Let me know how you get on

Best regards

Job

email (option): Jonnyob1@googlemail.com

Dragging the old "professional hat" out of the cup board I would proffer this .

Turn the case out of plain carbon steel.

It will be easier to machine for starters.

Plain steel heavy wall extruded steel tube is available in a much larger range of sizes than stainless tube so sourcing of feed stock will be much cheaper.

When you finish the machining get them heavy dull zinc plated ( Aluzinc would be even better )

I have a funny feeling that the original case is actually slilcon ( transformer ) steel in the first place.

Bike Beesa

trevor

email (option): wariron@tpg.com.au

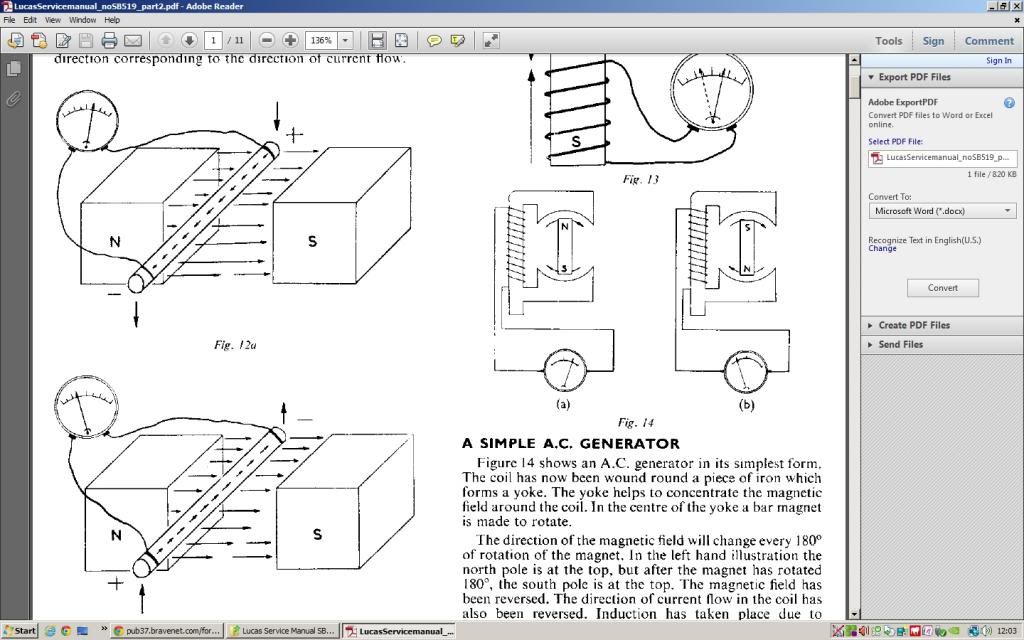

What about this then?...

'Where a Lucas dynamo differs from a simple DC motor is that there are actually two sources of magnetic field within the unit. The first is a soft-iron core which is what retains the magnetism when the engine is not running. However, this is not a particularly good magnet and the amount of magnetism it retains is relatively small and certainly not enough to generate the 45-60 Watts required by a classic motorbike. But it is just about enough to get a small current flowing in the coil when the engine is first started.

This is where the ‘field coil’ (a secondary coil within the dynamo) comes in to play. Some of the output from the generator coil is fed back into the dynamo through the field coil which then generates a secondary magnetic field (hence the name) of its own. This magnetic field is stronger than the residual field from the soft-iron core and therefore induces a bigger current to flow in the coil. More current is therefore supplied back to the field coil, giving an even greater field strength, more induced current in the coil, and so on until an equilibrium is reached for a given engine speed'

No mention of the dynamo body.. but this specifically describes the source of residual magnetism and the secondary field..(the soft iron core and the field coil). Also, whether it is or it isn't, I think it is a bit of an assumption to suggest the body is made from a 'special' material when there is no evidence at this point to substantiate that......Ian

email (option): ian@wright52.plus.com

I agree with most of what you say but the magnetic field is not just pointing at the armature it flows in a loop through the soft iron core, round the yoke (the body) "through" the armature and back to the soft iron core.

The illustration you have posted shows an AC generator...or in other words an alternator...not a DC generator (dynamo)...Ian

email (option): ian@wright52.plus.com

sorry Ian you will probably have to make one and see what haappens

email (option): roger.beck@node6.com

I know its an AC generator but it was the best illustration I could find to demonstrate the principle of the magnetic field loop.

In our dynamos the action of the commutator reverses the connection of the windings to the external circuit when the potential reverses, so instead of alternating current, a pulsing direct current is produced.

Stainless 431, magnetic and easy to machine my book says.

Cheers Pat

OK..I 'rang a friend' who is an expert in this subject to clarify this gap in my knowledge...It is indeed the case that the body has a function other than holding everything together in this type of (bi polar) dynamo.

It just goes to show, much of the published information doesn't tell the whole story....

His 'Best educated guess' was that a body manufactured from a magnetic grade of Stainless Steel would work..but the only real test of that ' educated guess' would be to make one and see if that is the case...

Sleeving a dynamo in stainless was considered a better option but may be problematical in the case of the Lucas dynamo due to the relatively thin wall where the body is machined internally for clearance..that would need to be checked. Also there is the question of whether a suitable tube size is available..(machining a sleeve from solid would be impractical unless you really HAD to do it)

So there it is..I will look at the possibility of sleeving the bodies but won't go to the trouble of making a s.steel body without being sure it would work correctly....

It's not all bad news though...I've learnt something I didn't know yesterday ....Thanks for all the input to this post.....Ian

email (option): ian@wright52.plus.com

What kind off stainles steel are you planning to use Ian only the high grades off stainles are non magnetic i am still intrested how it works out, exutly it might be benefical to use non machnetic stainles .

exutly it might be benefical to use non machnetic stainles .

email (option): evandeweerthof@yahoo.com

V8 Erik

Please read previous posts to see why non magnetic stainless is a no no.

Ive read it  as long the core off your coil is steel it will not affect the flux much as long as there is small magnetic field present in the core off the mildsteel core off the coil, im no exepert in this field but ive done simler experments whit hv and lv electrics, i can do some testing if needed ive got the equipment to annilyze it

as long the core off your coil is steel it will not affect the flux much as long as there is small magnetic field present in the core off the mildsteel core off the coil, im no exepert in this field but ive done simler experments whit hv and lv electrics, i can do some testing if needed ive got the equipment to annilyze it

email (option): evandeweerthof@yahoo.com