Suppose I could set the timing with a timing light, would that be 21 degrees BTDC ?

I allready use the timing light for the contact points.

John

email (option): john.kater@chello.nl

Hi John..7/16" BTDC is 38 degrees BTDC expressed as crankshaft rotation. Due to production tolerances in the various engine components this figure should be verified for the individual engine using a degree disc (and a depth micrometer to verify piston position)..Ian

email (option): ian@wright52.plus.com

Ian, 38 degrees seems so much, but you must be right. How did you caculated this ?

My calculation is as follows: 360 degrees equals 188 mm piston travel. The question is then how much degrees is 11,1 mm. My formula is: (360 : 188) x 11.1 = 21 degrees.

John

email (option): john.kater@chello.nl

Is there a „trick“ to getting the bloody ignition right??! I spent 2 hours at the weekend fighting with the damn magneto trying to get it correct and every time I tightened up the mag pinion it went all to crap! I’ve tried everything from gently pushing the pinion on to whacking it with a hammer. Yes I have lapped the pinion onto the shaft so it should hold. Sometimes it goes like a dream, one shot and I’m a rabbit of positive euphoria and other times, like yesterday, …words fail me (or at least those which won’t get me banned from the forum). I’ve set it advanced and am using the retard lever to correct it at the moment. I’ll have another go when my pulse finally comes below 150!

John. I don’t think you can just divide 360°by the stroke, the piston travel varies considerably with each degree of crank rotation, from a lot at mid stroke to not a lot at TDC and BDC.

Cheers

Pete

email (option): petercomley@web.de

Definitely more complicated, you need to know the stroke, the centre to centre length of the con rod and then do a bit of maths with sines and cosines.

The dreaded wikipedia has a page on piston motion equations.

Pete, I've always had this problem, I now set the piston at 7/16 BTDC and set the mag so there is a slight bit of travel before the points open. When I tighten the nut, the slip on the shaft turns the mag to the correct spot of the points just stating to open and the nut is tight. I can now do it right every time, but it took a lot of practise. Works fine for me. Like you, If I dont do this, tightening the nut will throw it off. I never understood why it does it, perhaps a new sprocket would help, the mag was NOS, so the shaft is fine, I also make sure it's nice and dry, I clean the sprocket with mineral spirits to completely remove any oil. Anyhow, nice to know I'm not alone! :-)

There's also this site with a calculator on it.

http://www.dansmc.com/mc_software2.htm

I read it as 36 to 37° for an M20 (stroke 94mm) and 33° for an M21 with112mm stroke. both 8.25 in conrods (209.5mm. I just wish I could get mine that close!!

email (option): petercomley@web.de

Thanks to you all for the eye opener.

John

email (option): john.kater@chello.nl

Alex has explained me his way of setting the timing of the ignition. It's slightly different as normal, but it worked for me, or for the bike in this case.

Ignition lever fully retarded, piston TDC, points just opening, fit the sprocket to the magneto, done! Of course you have to set the piston on the right stroke.

Cheers Ynse

I can't see why, if your going to the trouble of finding TDC, why its a problem to find 7/16" before TDC with ignition lever advanced & know your timing is correct.

That method is bad practice for several reasons & makes too many assumptions about the workings within the Mag.

Absolutely..If you time it with the points just opening, the piston at TDC and the adv/rtd lever in the fully retarded position you are making the assumption that when the lever is returned to the fully advanced setting you are at 7/16" BTDC.

This is not the case as the total piston movement covered by the range of the levers movement is considerably greater..So you would then,in fact, have the ignition set too far advanced..Additionally, you have still not solved the original problem of the position of the contact breakers (just opening) and the position of the piston changing in relationship to each other when you tighten the mag drive gear nut..That can happen wherever you choose to position the piston....Ian

email (option): ian@wright52.plus.com

Alex has been doing it for years now with good results. I just was curious and tried it and I was quite happy with the result. If you want to do it the 'official' way is up to you of course.

I'm with Fred and Ian on this one. Manufacturers settings vary from 1/8" BTDC to 1/2" BTDC. But the lever movement is about the same for all models. I don't know how this logic can apply? Ron

email (option): ronpier@talk21.com

I don't see how this method can possibly produce accurate ignition timing unless the timing figures for 'a bike' correspond exactly with the movement of the adv/rtd lever.

Explain please...Ian

email (option): ian@wright52.plus.com

Like Peter, I often find the points position has altered after tightening

Even lapped in gear & shaft doesn't seem to help

Just wish I could overcome this annoying situation

Job

email (option): Jonnyob1@googlemail.com

I have the answer to this problem...a modification to the mag gear etc. that enables infinite adjustment without removing the gear. So the timing can be set 'close' and then fine tuned in a similar way to how a car distributor can be adjusted..I've prototyped it and had it running on a bike without any problems...The real problem is I can't get the parts made at a reasonable price, so the project is a non starter commercially. I've timed scores of engines but still encounter the same problem myself..sometimes it will take multiple attempts to get the setting accurate . It's a real weakness in the design when accurate timing is so important....Ian

. It's a real weakness in the design when accurate timing is so important....Ian

email (option): ian@wright52.plus.com

Hi ian

I don't suppose you would be willing to share the details of the mag gear modification?? If it's a commercial non-runner you would be doing the community a favour and helping to reduce my intake of beta-blockers significantly.

A few beer tokens could be exchanged

Cheers

Pete

email (option): petercomley@web.de

Me too. Sometimes up to fifteen attempts at getting it spot on! And when I have on the very rare occasion, got it spot on at the first attempt....I just don't believe it and keep turning the engine over to check it again and again  Ron

Ron

email (option): ronpier@talk21.com

Hi Ian, maybe you should patent the idea..?

Just a thought...!

email (option): horror@blueyonder.co.uk

Are people that are having repeated problems using a spring washer or just nut without I wonder.

If its a case of holding the armature from turning then would a screwdriver slot cut in the end not surfice?

I use a shish kabob skewer and Hans method. Works sure fire each and every time!

Go see the technical section and download that splendid article.

email (option): britool51@hotmail.com

Lovely sunny day at last and I thought I’d do an hour or so in the shed then go out for a ride.

Result, ALL bloody afternoon setting the timing on the M21!

Dial gauge, head off, lapped in pinion and shaft, the lot! Still just a trial and error process!

Ian could you please give us an idea how to make a doda as you described last year?? Beer tokens could be persuaded to change hands , life is too short!

, life is too short!

Cheers

Pete

Quote Ian Jun 12, 2012

I have the answer to this problem...a modification to the mag gear etc. that enables infinite adjustment without removing the gear. So the timing can be set 'close' and then fine tuned in a similar way to how a car distributor can be adjusted..I've prototyped it and had it running on a bike without any problems...The real problem is I can't get the parts made at a reasonable price, so the project is a non starter commercially. I've timed scores of engines but still encounter the same problem myself..sometimes it will take multiple attempts to get the setting accurate . It's a real weakness in the design when accurate timing is so important....Ian

I have been thinking of changing timing gear plate so you can remove the idler pinion. You leave the magdyno pinion firmly in place and you remove the idler pinion. Once the idler pinion has been removed you can rotate both engine and magneto in to the correct position and then put the idler pinion back in place. I have tried this and you get close enough to be able to adjust the points a little to get spot on. The timing gear plate has to be changed in a way that it will do it's job as it should once the ignition timing has been done.

It can also be done this way by removing the complete timing gear plate but you have to undo the crankshaft nut to be able to remove the plate and I don't really feel like removing that nut to often.

Henk

email (option): ahum@quicknet.nl

Henk; sounds OK, now has anyone got a way of modifying the plate?

Cheers

Pete

This modified plate should be as rigid as the original plate. As I usually get the timing close enough in one go I never bothered to do anything with this idea but it would make it very simple.

Henk

email (option): ahum@quicknet.nl

I guess the plate could be cut to just allow the idler pinion to be extracted and then use something like a glorified washer to retain the idler. The 3 mounting bolts for the plate would remain and the missing rear location point on the idler pinion spindle shouldn't make much difference to the rigidity (?)

I have a few old plates around so I may give it a go.

On the subject of the plates, is there a trick to getting a new bush fitted? I have a bush and I suppose I need to rivet it on and then ream to size, anyone got any tips?

Cheers

Pete

I've just read halfway through this post before I realised it's an old one revisited

I also realised I have a vernier mag sproket (probably like Ian is descrobing) in the garage that I bought for a manual adv/ret mag and didn't use. I'll dig it out and post some pictures.

The piston travel converter is very good and I found this fraction/decimal/millimeters table is a great help too.

http://www.hamuniverse.com/antfrac.html

I have a copy on my garage wall

email (option): horror@blueyonder.co.uk

I've had a look in the garage and found the vernier mag sprocket. I bought this for a Dommie project. I bought a competition K2F mag with a manual adv/ret and as I had to buy a sprocket for the mag, I got this one. When I stripped the Dommie engine, everything in it was a bodge and easier to get another engine. It's been sat in the garage every since, I even bought an ES2 engine to go in it, but then bought an ES2 so that was pointless. I'll use it one day :-)

There are 27 holes in the base and 28 in the sprocket so only 1 hole lines up at a time. By using the pin in different holes you can adjust the timing a fraction of a degree. It's been a long time since I got it so I can't remember the increments.

I know this isn't any use on an M20 but thought I'd show you

email (option): horror@blueyonder.co.uk

I was afraid it might look like that!

Similar to the venier used by AJS.

Possibly a bit beyond my engineering skills. I'll think about the idler pinion variant or learn to live with the original method until I'm retired and have time to hone my metal bodgery abilities!

Cheers

Pete

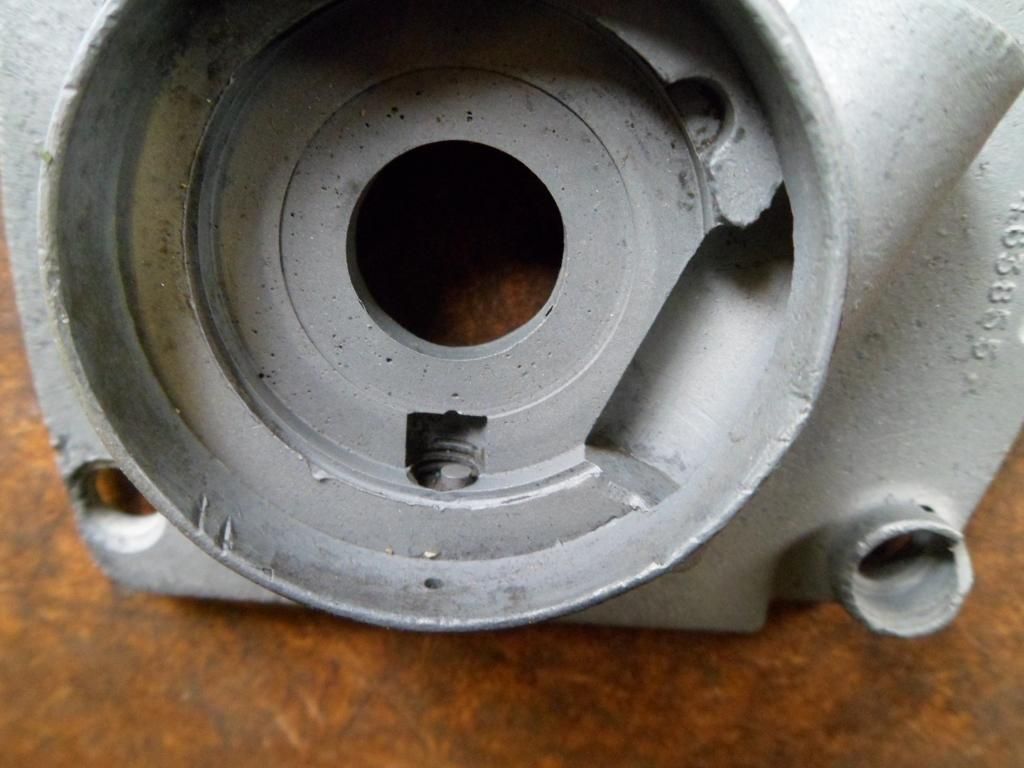

Just a thought but how about finetuning the timing by turning this little excenter pin? It has nothing to grab on so I presume it is set by the manufacturer to get the best spark at the right spot but an easy modification could be made to turn the pin... Let me know what you think of it.

Regards, Michiel / Holland

Isn't all this modifying etc a bit of overkill. Once the timing has been done correctly it should never need altering again. Apart from maintaining the correct points gap that is. Altering it at the mag pinion will only be required after the bottom half of the engine has been stripped or the mag removed.

It's true Kieth...The awkwardness of setting the timing is only going to drive you mad infrequently. Part of my desire to make the whole procedure less stress full though is to experiment with different timing settings on the oversize engine I run...and also to experiment in a similar fashion to try and determine whether lead free petrol...which has very different burn characteristics to the original fuel..will run better on an alternative setting.

At the moment I take a great deal of care to set the timing accurately at 7/16" fully advanced as laid down by BSA. However, is that setting still the best one with modern fuels?..I don't know. Testing a number of different settings in a short period of time with the current set up might cause a meltdown in the head...and not the bikes head

...Ian

...Ian

email (option): ian@wright52.plus.com