My 16H engine is now back together after its recent repeat valve guide problems and I'm attempting to address any possible causes with a view to avoiding it in the future.

It has been suggested by a reliable source that excessive guide wear is often caused by an over-rich mixture. Internet research indicates that the large quantities of carbon produced form an abrasive coating on the valve stems.

I have been aware since the initial build that the bike ran rich - considerable blow-back onto the oil tank and a sooty rear stand. It is difficult to be precise though as all 16Hs do this to some extent and the bike runs very well.

I can't find any details of how high the float level should be on these carbs. Presumably it is not normally critical as there are alternative mixing chamber nuts which raise or lower the level. Side-valvers traditionally have the short nuts which means a higher fuel level. I've now fitted a 'long' nut and can't detect any difference on a ride round the block.

Examination of my carb in action shows that as the slide is lifted, roughly at about 1/4 throttle and above, I can see droplets of fuel being blown backwards out of the inlet. This occurs whether the throttle is opened slowly or snapped open.

This richness (it must be pissing fuel in) seems to be at the transition between cut-away and needle. I'm running a 6/5 slide so can go one step leaner and needle jet is a 107 as standard. Needle is dropped as far as it will go.

One oddity (or it seems odd to me) is that tickover races with the pilot air screw fully in.

I've tried substitution of all parts, collectively and individually, including an NOS body, but not the jet block as the Norton type are nigh-on unobtainable. I'm not detecting any difference.

These instruments don't seem to have any accurately sized pilot jets and I'm puzzled as to where the restriction occurs. If my jet block has been 'got-at', could this be allowing fuel to squirt into the inlet tract behind the main jet ?

Any thoughts would be appreciated. I'm going round in circles with this one and I'm getting a bit fed up with staring into the spare carb wondering how I can tune it for any less fuel at smallish openings than I'm doing at the moment.

...at this rate, it's going to get a 'Concentric' on it, I can understand those !

I'd first rig up a 'sight glass' affair with a bit of tubing coming off your float bowl in place of the carb junction. That will allow you the approximation of x-ray vision to see the fuel level inside your float chamber. Next, if that's ok (and a monobloc is usually much harder to get the float level wrong than a concentric) time to inspect the needle jet. The needle jets on old monoblocks seem to always be worn because the needles are constantly wearing on them. I'd take out the needle jet and measure it with a gauge plug, or suitable drill bit size to check the size of the hole. Don't be surprised to find it oblong. A worn needle jet can mimic the symptoms of an overflowing bowl.

BTW, I'm currently dealing with this on my dominator, though it has a 376... slightly different but much more similar to your carb than a concentric.

Hope that helps.

Kevin

Thanks Kevin. I haven't yet put a sight gauge on the float level (easy enough to do with a spare blanking plug whilst everything's in-situ) as I don't know what the level should be. I can see with the cap off the chamber that the level is not ridiculously high.

I've tried substituting needle jet and needle with new items from Martin Bratby. His stuff is usually good quality and it would be odd if it gave the same results as what I had.

I can find no documentation about the 'Non R' Norton 276 body / jet block with the small flat and two pilot air holes. It also seems as if the Norton body has a shorter locating dowel slot which means that it can't act as an overflow on the Norton carb.

Perhaps with modern fuels, I need a much smaller needle jet ? This raises the question though of why no-one else is having the problem.

It seems I'm on the same journey of education about these things as you, but to my mind as long as fuel isn't pouring out of the needle jet, the level is ok. On other carbs I've fettled, usually float level has to be grossly starved or flooding to be an issue. In my experience, most folks weaned on a concentric assume that monobloc flooding is always caused by float height, whereas it's always been needle jet wear. That's at least on the ones I've dealt with.

Rik,I am in Australia and sell Amal parts, including a lot from Martyn Bratby,I have some new old stock Norton 16H jetblocks, price with postage would be 33 pound, as you say no one has them. The float level you wont find written anywhere but it is pretty rough on the 276, it should be just below the top of the needle jet but can be more than one eigth of an inch down and still be fine, of course if it is too high it overflows. Have you got a good gasket under the jetblock that can compress as if you use a rock hard gasket it can cause petrol to leak and cause richness.

John

email (option): ukcarbs@hotmail.com

Rik, what exactly are the differences between the jet blocks?

When I assembled my B4 carby, I never knew this, but fitted an N.O.S. jet block, have no idea what type exept it was 276, and fitted, could well be from a G3WO Matchless, no ill effects though, can you see the difference from the outside?

From what I learned recently, from various people, is that you should fit larger jets, to compensate for modern fuel, same as advancing the ignition more than the 40's spec's.

Have contacted John, and cc'd you on it.

Cheers,

Lex

email (option): Welbike@welbike.net

Lex 276 have four types of jetblock.One with 4 holes around the base to suit bodies with the four holes mainly pre war but also later AJS/matchy and some others,then the common one with a 1/4 inch hole at the front to match the body, a left handed version that has the holes on different side at the back of the jetblock and lastly the Norton type that has two 1/8 inch holes at the front that fit the body without the 4 holes or the 1/4 inch hole. Hope this helps John

email (option): ukcarbs@hotmail.com

Thanks John, but as I always say a (even bad) picture says more than a thousand words, what about this jet block?

It has the 2 holes on the front, not both 1/8" and it has a hole on the back, for the "normal" fitments??

Note also the silver painted body, later ones were varnished.

Could the above jetblock be a "universal" type, that fits everything? (exept the prewar types with the 4 holes at the bottom)

The army wouldn't have liked it that there were more then one type 276 jetblock!!

Lex

email (option): Welbike@welbike.net

John, I would certainly like a jet block. I did speak with Martin Bratby some time ago and he said that he could assemble one for my spare carb from a used base and new slide guide, but I'm not very good at getting round to that sort of thing if the need is not immediate. It's not like picking one up at a jumble.

I'll talk to Lex about our joint requirements.

In the meantime, I've checked my fuel level using the long mixing chamber nut and it seems OK. As far as I can tell, the top of the spray tube comes to roughly the same height as the top of the brass blanking plug on the pilot screw drilling. In that case, mine seems in order.

I'm now left thinking that the jet block is the only possible cause.

I'm probably being a bit dense but I can't understand how a mixing chamber nut gasket that is not leaking on the outside can be allowing fuel to pass into the inlet. The Norton carb doesn't seem to have the same overflow facility as the 'R' carbs so perhaps there is an intermittent flooding problem ?

Incidentally, a metric grease nipple with the ball removed seemed to be an easy replacement for the float chamber drain screw and allowed a length of tube to be pushed on. Strangely, my spare (earlier) chamber has a larger plug - it seems that the thread was changed at some point. An M5 nipple went in cleanly enough on the later chamber.

Lex, there seems to be a little confusion about which is the front and back of the jet block. The item that you have there is from a standard 276R - fitted to every machine other than Norton, I believe.

The large hole on the air side mates up with a slot machined into the throat on the 'R' carbs and is the pilot air entry. On the Nortons, the inlet tract is not interupted but the back of the jet block is flat with two tiny holes so the air has to find its way down the side of the jet block.

I don't think that your spare block would allow any pilot air entry in a Norton body. Perhaps oddly, all the castings, including early Norton 276s seem to have the 'gusset' under the mouth of the carb which is machined out on the 'R' version. Can you see it in your first contract Big 4 studio shots ?

I think that I'll tap out my jet block for a look under the magnifying glass tomorrow so I'll post comparison photos.

If the jetblock gasket is too hard petrol can sit below the jet block and cause richness, if the thread is worn it will also seep out. If you get hold of an original Amal tuning brochure, it states,if jetblock is not tightened up by washer and nut, richness will be caused through leakage of petrol, same certainly applies for rock hard gasket. About 1950 they made the internal horizontal hole bigger on the float chamber to let more fuel in to the carby and therefore used a bigger plug, the bowls were marked /M for modified after the bowl number. Regards John

email (option): ukcarbs@hotmail.com

Well I had a look on my B4, and there's no flat spot at the back of the jet block, and the engine runs just fine, done over a 1000 miles now, so not in a hurry to change things, it must get the air from somewhere though??

Can always file a flat spot on the "normal" jetblock I think.

Cheers,

Lex

email (option): Welbike@welbike.net

Spot on Rik that is the correct jet block for the 16H Norton.The front of the jetblock is where the choke slide fits.

John

email (option): ukcarbs@hotmail.com

I can't add much to the above posts, other than my own experiences......

My 16H has always run on a NOS 276 carb......I originally ran it with the standard block and it always ran a bit rich, silencer sooty and with fuel blowback all over the oil tank (fitting the pancake-style air-filter helped stop the mess, but not the blowback...)

I then fitted the correct (NOS) Norton-type jet block.....no bloody difference...!!!

On the one occasion I played around with the needle, dropping it one up and one down the notches, the thing wouldn't run smoothly at all...popping and banging, etc.....pilot jet, main jet, throttle slide adjustment screw, air screw....nothing will change the richness......plus, all parts are genuine NOS ex-WD Amal........I've also tried smaller and bigger genuine jets, 6/3, 6/3.5, 6/4, 6/4.5, etc, slides.....I give up....

Were they all like this......?

Thanks for your comments, Steve. It pretty well confirms what I'd been finding. I'd pretty well come to terms with living with the symptoms but if they are linked to my valve guide problem then I've got to find a solution.

I really want to put some serious miles and long trips onto this bike but as things stand, I can't trust it.

There must be a way of leaning the mixture off without causing it to run like shite.

I'm puzzled as to why the Norton has a different jet block etc. to other bikes. The Norton engine doesn't appear to have characteristics/requirements that are different to any other bike and the carburettor is just a fuel delivery mechanism.

I would have thought, for instance, that it would run on the same 'concentric' carb as any other bike if you were to make that change...

Perhaps you should consider a modification to a flange mounting and fit a 'standard' 276 on it?...or perhaps look at modifying a 'long neck' 276 off a Triumph to the stub mounted pattern...Ian

email (option): ian@wright52.plus.com

I may find I have the same problem with my 16H when I get to run it. If that is the case I'll just buy a new car from Amal and have a reliable bike. It will last my lifetime. You can set them up how you want them with Amal as well.

http://www.amalcarb.co.uk/buildCarb_PreMono.aspx

A Carb is a wear and tear item the same as a tyre. We're using 70 year old carbs and expecting them to be perfect. I've had 40 year old carbs on bikes that haven't worked properly or seem to have the internal jet blocked. Amal have told me there's not a lot you can do when this happens. I've got a set of concentric's that my mate is going to put in an ultrasound tank to see if we can clear a blockage (the effects of petrol on fibreglass tanks) but I'm not holding out much hope. So it will be new carbs.

It transforms the bike as well, no more popping and banging etc, and save a lot of time trying to set up worn carbs.

email (option): horror@blueyonder.co.uk

Horror, that may well be, but we're using N.O.S. parts mostly and still blowback issues etc. I don't mind too much, as long as it starts and idles OK, I'm happy!

But will try out a proper 16H jetblock on my 2nd B4, and have a 16H with a totally worn out carb, that needs to be done too, see what will happen!

Lex

email (option): Welbike@welbike.net

I see I accidently put "new car" instead of "new carb"... was that a freudian slip

I appreciate what you're saying Lex, and I hope you get it sorted, but it's still parts that have been kicking around for 60+ years. Maybe the new Amal's are improved and there won't be these problems.

I'm expecting to have the same problems with my 16H, I've got an almost new carb for a Norton Model 18, but if that doesn't work well I'll buy a new one.

email (option): horror@blueyonder.co.uk

I agree with Horror..You can't neccessarily keep endlessly recycling parts. I fitted a new 276 on my M20 about 5 years ago..it was easy to set up, has performed well and predictably and I've never really looked at it since it was fitted. Why is it people fit new pistons and big ends as a matter of course but expect carbs, girder fork springs, saddle springs, clutch parts, gearbox parts etc.etc. to go on for ever?..Ian

email (option): ian@wright52.plus.com

Ian, the easiest way to gain a 276 'R' type carb would be to use the 'R' jet block and machine the tunnel for the pilot air inlet into the floor of the carb mouth. Later castings all have the 'gusset' underneath which would allow this. Lex has found a photo from 1937 showing a 276 without this extra casting but it seems likely that one standard casting was used once the 'R' type became available.

The Norton doesn't 'need' a different carb, as far as I can tell but it's use of what was the original version of the 276 appears to follow on from the practice that saw the WD use the 1937 pattern engine rather than the 1938 type when it became available.

There is surviving correspondence (it's on the web somewhere) between Amal and the Australian importer in 1946. It makes it clear that the 276 was developed from the Type 76 for use by the WD Nortons which at the time were the only machines fitted with air filters.

For reasons that were not detailed, there was shortly afterwards a revision to the pilot air inlet and this revised ('R'suffix) carb was taken up by all the subsequent WD suppliers. Amal continued though to supply the earlier pattern to Nortons.

Was this because it worked better and they didn't wan't to fiddle with it or was it down to vast stocks and spares simplification ?

It does perhaps sound as if the Norton needs a better pilot air flow but that raises the question of how 100,000 of them saw such extensive use. I can't help wondering if the more volatile modern fuel is being sucked neat in too large a quantity via the pilot drillings without enough air to correct the mixture. In effect almost squirting unvapourised fuel into the inlet tract.

In answer to Horror's question, both Lex and myself have been able to put together carbs using NOS wearing parts and I suspect that we both started at a time when new manufacture was simply not available.

I'm now trying to pluck up the courage to take a round file to the throat of a, NOS 276/011

Good luck Rik, I hope you sort it and have a reliable 16H

email (option): horror@blueyonder.co.uk

Yes it was the war Office in Britain in I think August 1939 that wanted to filter the air going into the carbs (for desert work)that caused them to change from the type 76(4 holes around the base) to 276 the 4 holes replaced with a 1/4 inch hole at the front that could be filtered. The 276 Norton body has the boss bit under where the air goes in at the front but no drillings so the air gets sucked down between the body and jet block and through the jetblock but obvioulsy not as efficient as the early 76 or standard 276 which would make it run rich and idle and from what I read here right through the range. In Oz lots of bikes have modern pod type air filters due to country dirt roads.

John

email (option): ukcarbs@hotmail.com

I've now been able to fit the NOS jet block which John sent through to an NOS body and have carefully checked things at every stage. I'm now running with a long mixing chamber nut to lower the float level (can't really work out why that should be necessary unless modern fuel is less buoyant or my float has become heavy with age (it doesn't leak). Main jet is 160 (170 std) and slide is 6/5 (6/4 std).

I am now seeing much less blowback from the carb although being brutal with the twistgrip can cause the poor thing to blow backwards. I'm still getting a sooty stand but haven't yet worked out how to do a plug chop on a bike with only the valve lifter to stop it. It does seem as if part of my problem at least has been caused by an enlarged pilot jet drilling in the back of the jet block (the oversize is not visible).

I have now been able to compare the two main types of 276 and at least have a better idea of how they work.

These are the major types of jet block - left to right - Type 76, Type 276R and Type 276

In addition to the single large pilot air inlet, the 276R (the BSA type) has a transverse drilling which acts as a drain (shown below just above the locating dowel) via the lengthened locating slot in the boss. The Norton block doesn't have this which means that if the float level is too high or the float needle is not seating properly, there are no external leakage symptoms but the excess fuel will be sucked into the engine (or blown back out).

It is worth bearing in mind, if anyone has a leak from here on the M20, fuel can only reach this drain by first overflowing out of the top of the spray tube and if this is occurring, no amount of tightening the mixing chamber nut will help.

The locating slot / drain opening on the 276R is 9/32" long and that on the Norton only 3/16" I almost wonder if it's worth enlarging on the Norton body and drilling the block through so that it too can overflow outside.

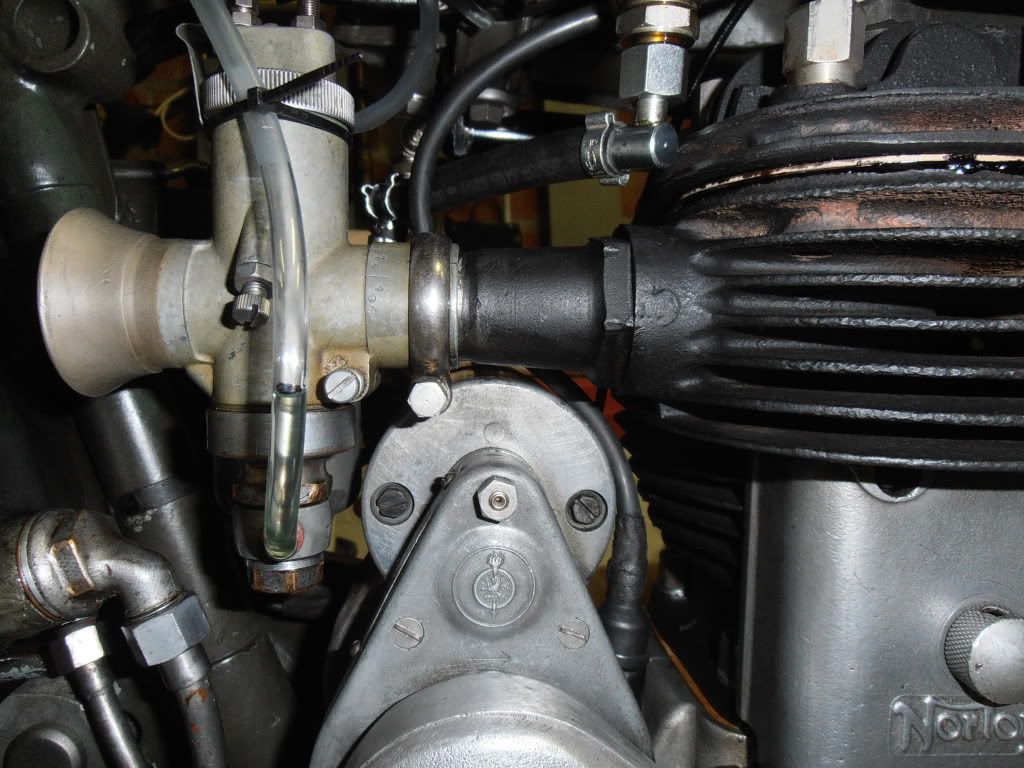

This image better shows the difference in the inlet tract to deal with the two types of jet block.

The back of the jet block, being the location of the non-removable pilot jet drilling is the same on both types (ignoring the aspect that this particular 276R has left-hand adjuster screws. The Type 76 doesn't have the angled air drilling from the inside of the block where the pilot air passes around the spray tube

Fuel feed to the pilot is from a direct boring from alongside the spray tube. The metered flow enters late in the inlet tract with any excess being drawn up in front of the (closed) slide.

Just for the sake of good order - the blocks look identical from under. Small hole is the pilot fuel feed.

...and even after all this investigation, I still don't really know why my engine seems to need pretty drastically different settings from standard.

hi rik,the other rick,is it worth taking the timing cover off and just checking your timing marks are spot on.

this blowing back seems to me that your inlet valve may still be partially open as the piston starts its upward stroke,

ie,partial vaccum to positive pressure.

in the case of an m20 one tooth will equal 10 degrees of cycle.

i think worth a look

hope this helps cheers rick

email (option): richardholt@rocketmail.com

I agree Rik. I mean Rick!

Factory marks on WD Norton timing gears ? That would be nice !

I don't think that's the problem and I'm pretty sure that the blow back is a symptom of the over-fuelling. Ian can confirm that the head had a coating of sticky gunge rather than a nice dry deposit.

The 16H runs a valve overlap of 27°-30° BTDC - 27°-30°ATDC and I've had the head off enough to confirm this several times. At TDC on the exhaust stroke, the two valves have equal lift.

Nortons of this period have three keyways in the crank pinion so it's possible to get the valve timing pretty well spot-on.

They are known for blowing back a bit, that's the nature of the beast. It's the quantity that's the problem with mine.

hi rik,just found this http://www.norton.uk.com/valtiming.JPG ,it is prolly not the answer to anything but seems there are several settings for the 16h over the years.not knowing the exact set up ,im prolly talking through the hole in my hat but is it possible someone changed the cams in the motors 70 year history,for a type not suited to this motor,that look the same but arn't,could this be causing the side thrust that is wearing your guides out? only my way of thinking,but if you have tried many variations with your carb ,maybe time to look elsewhere.

cheers rick

email (option): richardholt@rocketmail.com

This is a very late addition to the Amal 276 correspondence - from a 16H Norton owner. I wonder if someone can assist?

I seem to have the earlier jet block with the ring of holes, but the later body without. It does not have the large down-sloping hole to the pilot gallery either.

So either I pay a large amount for uncertain results, or I trawl auto jumbles or what?

Can I drill longways through my block to provide a hole to the tip of the pilot screw gallery? Or maybe directly through the wall of body of the carb. That would at least provide a direct air passage.

Obviously it would bypass an air filter but I don't have one anyway.

I might try it and use JBB weld to fill it in if it does not work. There is a brass bush in the closed end of the gallery and a hole straight through that might do the trick.

Thanks

David

email (option): daifromwales19@gmail.com