Something that's always bothered me that someone may have the answer to...

BA threads are generally used for instruments such as switches,speedometers,electrical equipment etc. In fact another name used for BA is 'instrument thread'

It seems odd therefore that this thread should be used (on M20s)in the primary chaincase and to hold the lower chainguard to the rear torque arm.

Are these threads in fact 3/16" cycle thread?

The two threads are very similar..the main difference being the thread angle...this is 47.5 degrees for BA and 60 degrees for cycle thread.(and the root and crest of the BA thread is radiused) The difference might explain the number of stripped threads that can be found in primary inner covers when 2BA screws are used.

Below are the other essential dimensions of the two threads....

Outside diameter (2BA)...185"

O.D.(3/16" cycle)....188"

Threads per inch (2BA)...31.4

TPI (3/16" cycle)....32.0

As these figures show the two forms are very close...any comments?.. A final possibility is that they could be 3/16 BSF..55 degree included angle..187" outside diameter...32TPI.....Ian

Had the same problem with Matchless twin timing cover screws.3/16th would go tight a few threads in and then discovered they were BA.

Ian, I think you are correct. I was dismayed at how loose the brand new 2BA screws were in my primary (primary in very good condition with no stripped captive nuts) and looked at this a while ago.

I have seen two BSA part numbers listed for the primary - EB379 and 1-4606. Both are listed as 3/16" (the EB379 is 3/16" x 13/32" and the 1-4606 is 3/16" x 1/2"). The thread isn't specified but I assume it must have been BSC.

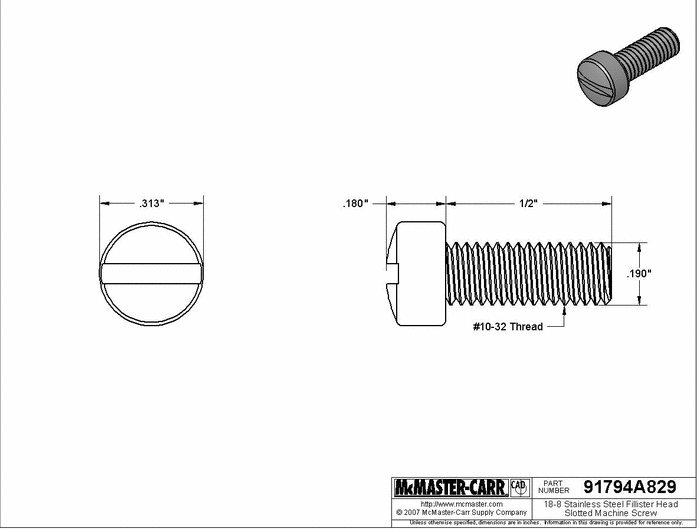

Of course 3/16" BSC (in my area anyway) are like rocking horse poop and I was wondering if a 10-32 Fillester that is available in the US wouldn't be a pretty good substitute for the chaincase?

I sent an email to this company and got the closest thing to "Piss off" I have seen - they are not interested in anything outside of the US so perhaps some of our forum associates could help out.

I think a 10-32 tap in a loose primary captive nut might work given the OD is only a hair more at 0.1900".

email (option): rays54@hotmail.com

If anyone needs anything from the States, I'd be more than happy to send it to you.

McMaster Carr only supplies business accounts. I used to buy thousands of dollares worth of things from them when I was in industry. They are overpriced, but they have what you need, except anything British!

BTW, I have 2 BA socket head screw in my primary chaincase. Fit just fine.

email (option): britool51@hotmail.com

With a little force you can get an M5 in there too

email (option): ahum@quicknet.nl

Yes, since I have my M20, (about 15 years or so) I've taken that primary cover off and on again numerous times, and the M5 still do their job

And VERY cheap too...

email (option): viaconsu # planet dot nl

M5 has the same thread angle as both 3/16" cycle and unified threads as described by Ray (60 degrees). Pitch for M5 is .8mm which equates by my calculation to 31.71 tpi. Outside diameter is larger than all the threads previously mentioned at 5mm (.197").

Subject to taking a final detailed look at the 5mm thread form this may be an alternative and would be more easily available in a filister head pattern. The pitch difference in practical terms is negligable...only .29 of a pitch over 1"..and the captive nuts are probably only approx 3/16" (.187")thick...though tapping to 5mm would be required I would think due to the difference in outside diameter. I would also like to try the N10-32 (UNF) thread suggested by Ray as it is still available in the States in the correct head pattern.

Here in the UK 3/16 cycle in the correct form is unavailable as far as I am aware...3/16 BSF might be available but it is unlikely I would think. The UNF screw could well be available here...

Some fastener threads are listed in BSA parts lists and as Ray pointed out they are shown as 3/16 dia....a detailed look at the lists is required I think to see if any detail the thread type but I think it is most likely to be BSC....

...Ian

I've found a UK supplier for filister head, stainless steel 10-32 UNFx1/2" screws. Has anyone tried these yet?

As a matter of interest the same things we have been discussing might apply to the clutch dome retaining screws....Ian

Ian, just looking through Dave Middletons catalogue, he states "For 3/16 BSC-use 2BA or 3/16 UNF"

Although he doesn't list 3/16 in Filister or cheese head....only pan head.

I have used stainless 2BA cheesehead that I bought cheaply from Stainless Steve. Ron

email (option): ronpier@talk21.com

I don't think advising to swap 3/16 cycle for 2BA is good advice because of the difference in thread angle and tooth form...that was the reasoning behind by original posting...Ian

You're undoubtedly right Ian. But I ordered a new set of screws from Drags, years ago and they sent me plated 2BA's. The cover has been off a few times with no stripped threads, and as mentioned I have replaced them with stainless. Ron

email (option): ronpier@talk21.com

I've always used 2BA in my various BSAs...mainly because I thought that was what they were supposed to have. I have had threads go more than once and have also had the fasteners feeling 'loose' in the thread as described in an earlier posting.

I guess it depends to a certain extent on how well used (worn) the inner cover threads are in the first place.

It is apparent 2BA is not the correct thread and it is definitely not the closest substitute. If a better alternative is available I'll use it.

As I have found a source for the N10-32 UNF screws in a filister head pattern and also in stainless steel I'll probably get them in...I just need one to try first to ensure the fit is good before ordering ....Ian

Okay, I've lost the thread on this one (pun intended). Can anyone summarise what threads ought to be used in BSA M20 primary covers, and what's generally the least worst option if we have to use something else?

email (option): dannydefazio@sumpmagazine.com

Hi Danny...BSA parts lists indicate the chaincase thread is 3/16" diameter. However,(so far) they do not indicate thread type. Going by what is used elsewhere though, 3/16" cycle thread is the most likely.

This is not available today in a 1/2" long filister head screw....the original type.

Many suppliers provide 2BA screws as an alternative but this is not the best choice.

Looking at all the available thread options three are better candidates as a substitute for the original than 2BA

1)N10-32 UNF

2)3/16 BSF

3)5mm

No1 is close in specification and available..it should fit without any tapping out of the threads but this needs to be confirmed.

No2 is not readily available in the correct fastener format.

No3 is readily available but is metric so not strictly 'at home' on the bike, although with a slotted head it makes little practical difference.. Also it is the furthest from the original screw diameter (approx .010" bigger.) So really the cases should be re tapped before using this one.

So in conclusion, in my mind 1 and then 3 above are the best options as replacements for the originals....Finally,3/16" threads were also used to hold the lower chain guard to the brake torque arm and to retain the clutch domed cover...so the same observations would apply to these applications ....Ian

Ian, thanks for that. But how comes one of you engineering types can't boot up a CNC machine and reproduce the original nuts and bolts with the correct thread and pitch form and whatever else it needs?

email (option): dannydefazio@sumpmagazine.com

Hi Danny...lots of different nuts, bolts, screws,studs etc.used...lots of money required...and lots of buyers needed....Ian

Ian, I thought the whole point of CNC machines was that you just punched some buttons, fed in some steel stock and went to lunch. But if you say the numbers just don't add up, I'll believe you.

email (option): dannydefazio@sumpmagazine.com

The advantage of a CNC machine is speed..I have worked on machines that could make 100 fully machined washers a minute.(6000 an hour)The more parts produced in a given time (the time you hire the machine and operator for) the less the unit price. However, there is an up front programming charge, so the more hours you run for the more components there are to spread that cost over, thus affecting each components price less.

If you walk in through the door with a really large order you get the price deals...because they want that job.

So, it's all about volume and time.

One thing the M20 market doesn't have is volume...I've never sold anything in high volumes and selling anything takes a fair bit of time...so a slow turnaround.

If you manufacture in quantity and at speed you need to sell in a similar fashion...it's simple economics. Otherwise you have a lot of parts (money)sat on the shelf for a long time...and how many times can you afford to do that?

Finally, CNC machining is a cheaper form of production compared to older methods of manufacture..but make no mistake...it's not cheap...The machines and tooling are very expensive, operators are well paid and the whole operation has to be run each hour to make a profit...and that is paid for by the customer...Ian

Thanks for that, Ian. Very interesting. But at least I know what to buy you for Christmas.

email (option): dannydefazio@sumpmagazine.com

Thanks Danny, I'll have a 5 axis machining center...starting price about £250,000..

...Ian

...Ian

If anyone cares... I have a McMaster-Carr account. I have a case of 10-32's in most sizes. Got a box of cheeseheads in my hand right now...

Dont know how any machine shop in the USA can make it without a McMaster-Carr and MSC account.

email (option): micran1234@yahoo.com

Hi Michael...So I guess you use these 10-32 fasteners in the applications we have been discussing? I have found a supplier in the UK..if you can confirm they are a good replacement for 3/16 Cycle I'll be ordering on Monday!....Ian

Well I haven't actually used them anywhere on my M20. 10-32 happens to be a very common machine screw in the states. I will certainly try one though. I will post my thoughts before days end.

email (option): micran1234@yahoo.com

Thanks Michael...Ian

10-32 ?

what does that stand for...

email (option): chris.astinbarker@btinternet.com

Hi Chris..N10-32 is the coding for 3/16 (approx) UNF..they use these number codings for the smaller sizes...not sure why but it is probably because most sizes below a 1/4" don't conform to an actual size in a similar way to BA threads.(which are also numbered).Ian

Okay. Tried the 10-32. No-Go. Got about a turn and a half and stops solid. I haven't paid enough attention to say if its outside diameter issues, thread pitch, or thread per inch.

What I can say is that it seams all my primary cover screws look like the thread crests are worn flat. If I had more time tonight I might have tried modifying the crest on the 10-32 to see if it helped.

I can perform more tests if anyone wants.

email (option): micran1234@yahoo.com

Did you try M5...

email (option): viaconsu # planet dot nl

Hi Michael...thanks for that...I'm surprised those screws didn't go in. I'm going to have a look and see if I have a 10-32 tap today in amongst my UNF stuff (which doesn't get used much). I have some scrap inner cases to experiment on...problem is I don't have a 10-32 screw lying about. Looks like a trip to the fastener shop.

Hans...I've used M5 in the past...I can't remember if I tapped the threads out. It seems like they should be as the diameter is appox. .010" bigger. Did you run a tap down the threads?....Ian

No tap used, they went right in with only slight persuasion

email (option): viaconsu # planet dot nl

Ian, I picked up a couple of 10-32 screws today and as Michael has said they won't go into good chaincase nuts freely.

However, on an old chaincase that has seen the wars I did get it to go through so I'm pretty sure just a kiss with a 10-32 tap and you would be in business.

They did go into the rear brake stay - I have a NOS one and the 10-32 was firm but went through without undue force. Again, a kiss with a tap and lovely fillester heads would be possible.

email (option): rays54@hotmail.com

Thanks Ray...I think they are what I will go for..Ian

Isn't also the battery strap originally this same thread for the acorn nuts? Ron

email (option): ronpier@talk21.com

I think you might be right Ron...where will it end?

...Ian

...Ian