As many of you know is very hard to find good original M20 girder forks.

To me it seems the only answer is to make them, but I need help.

No I don't expect anyone to put their hand in their pockets, I'll fund it myself.

For those that don't know my work, many years ago I manufactured chassis and suspension for Cooper Racing of Calne.

We've manufactured parts successfully using techniques that will be required to make the forks.

Now for the point where your help is needed!

What I require is a good set of original forks to copy.

I'm in south Yorkshire and will pay the carriage if your not local.

To speed things up I'll make plaster casts from all the castings.

The rest is easy to CAD model in solidworks.

This way you can have your forks back as soon as possible.

I will try to make all the new parts the same as the originals so that a spares supply will be available.

Thanks for reading,

Mark

email (option): pes.sales@btconnect.com

Hi Mark,

What a good initiative! Which type M20 girder fork are you going to reproduce? There are at least 3 variations, a 1939, 1940 and later model. These 3 variations all have different partnumbers.

Good luck with your project!

Regards,

Bastiaan

email (option): wdmotorcycles@gmail.com

Thank you Bastiaan, I knew someone would throw a spanner in the works.

I would be planning on doing the later ones as used in 1943.

email (option): pes.sales@btconnect.com

email sent

come on then Bastiaan, pt numbers, don't be shy!:grinning:

Replied

email (option): pes.sales@btconnect.com

Where in South Yorks are you Mark.

email (option): colinmbrindley@btinternet.com

Between Doncaster and Barnsley Colin.

email (option): pes.sales@btconnect.com

I just bought a set on Fleabay today ... I think they are the right one for my 43... Going by the info given in my thread. Ill post pictures as soon as I have time. Too bad Im not in England or id bring them by. Hopefully I wont need any new parts but its great to know that someone will be making some available.

email (option): wadeschields@mindspring.com

Hi Mark Im local to you, sent you a message.

email (option): colinmbrindley@btinternet.com

Thank you all for the offers so far, but this request would be better suited to those who are in the process of doing a build. Or those that are planning to do repairs or service. Obviously as I would need to strip them to their component parts they would be cleaned and any repairs after discussion done free of charge. Not forgetting that they would be assembled again before returning.

email (option): pes.sales@btconnect.com

Hi mark

I have a set here you can borrow

But - they are early shorter type which are even more scarce than the later longer fork

They differ by 1/2” in total length

Drop me a line if you need - I am in no real rush for return of these

Br

John

email (option): jonnyob1@googlemail.com

Rob

email (option): robmiller11(a)yahoo.co.uk

If this is the Mark Cook of B50 scrambler engine fame, well he has a brilliant reputation. He's one of those folks who doesn't know how to do a job badly.

email (option): jeremy@clogmaker.co.uk

Rob

With the techniques I use the paint work shouldn't even get marked. I use various waxes as release agents for taking moulds, so soap and hot water will clean it off.

email (option): pes.sales@btconnect.com

I have a set here you can borrow

But - they are early shorter type which are even more scarce than the later longer fork

They differ by 1/2” in total length

Drop me a line if you need - I am in no real rush for return of these

Br

John

Do you or anyone else know if their are any other differences other than the length?

There was a mention of three different versions??

email (option): pes.sales@btconnect.com

I try to do my best within price constraints and customers willingness to work with me.

email (option): pes.sales@btconnect.com

Hi Mark, thanks for making that clear, sadly I don't have a set loose at the moment so I can't help, and I think you would find as much demand for the short ones for peoples early projects.

Rob

email (option): robmiller11(a)yahoo.co.uk

Mark as far as I'm aware, the three different forks are

1) the early 39 forks where the speedo drive is through the brake plate and the legs are parallel

2) the next pattern are the short forks with a splayed left leg for the hub speedo drive.

3) the 3rd pattern have the same splayed leg but the tubes between the damper and wheel spindle are 1/2" longer. The change seems to have taken place at or during contract C 7287 which look to have been supplied during 1941. (no modification to the central mudguard casting was made, a 1/2"spacer is added)

This vague illustration of which I have deciphered the fuzzy figures is for the long forks. Ron

email (option): ronpier@talk21.com

My October 1941 project bike came with short forks & a brake rod as original spec

Curiously - the frame no sequence comes from 1940 - resurrected over a year later & applied

I think the change came later in 1942

Mark

Tin has detailed the basic differences - the main being the additional 1/2”

Casting marks up to about 66-2014 located on the front all appear to be short versions

Br

Jo’b

email (option): jonnyob1@googlemail.com

John. Henk tells me that from his large collection of original photographs, the first bike with out a brake rod and fitted with the mudguard spacer (long forks) is frame number WM20 25307. Which is from the early stages of contract C7287, which was demanded in 1940 and supplied through 1941...So I don't know then for sure. What is your frame number out of interest? Ron

email (option): ronpier@talk21.com

Hi,

See this for the difference between a 1939 and 1940 fork, both are 1/2" shorter then the late type.

http://pub37.bravenet.com/forum/static/show.php?usernum=3155626639&frmid=16&msgid=1428224&cmd=show

Regards,

Bastiaan

email (option): Wdmotorcycles@gmail.com

Hi Ron

My bike carried registration plate ZD 3081 & left factory with frame/engine no WM20 4547

It seems to have lived its service in southern command -IDF - & came with balloon tank- short forks - brake rod & a Bakelite damper knob

This is an early number associated with 1940 bikes but seems to have reappeared in late 1941 - stamped on a typical 2nd pattern frame

Less than 100 bikes in that batch - I will have to check the records to confirm how many

Br

Jo’b

email (option): jonnyob1@googlemail.com

Thanks for confirming that John. So your bike is an early Deluxe model, but despatched at a later date? So a bit of an anomaly and doesn't really help at confirming the date of the change in fork length. :confused:

According to the Air Publication parts list for January 1944. The RAF outfits were still fitted with the 1940 short forks throughout the war. So they either had reserve stock or were still producing them. Ron

email (option): ronpier@talk21.com

I think we may have discussed this before, this is the theory that I seem to remember?

The short forks have a different part number for the spring.

Pre war the M20 and M21 were designed as a sidecar machines or budget solo.

The standardised Military Model as it became in 1940/1 was a solo machine.

The spring became lighter to give better springing, I can't remember was it a different gauge of wire like on a Norton Big4 /16H, or a different number of winds?

The lengthening of the forks didn't really give more ground clearance but made up for the loss of ground clearance when the front fork action was softened?

So when a batch of combinations was manufactured later on they reverted to the pre war set up so the extra weight of the sidecar didn't make the front end droop.

Rob

email (option): robmiller11(a)yahoo.co.uk

The lighter spring would have been a rattle fit on the spring scrolls if it was a smaller gauge wire so in that case I'd have thought there would have been different spring scrolls as well, also with a different part numbers...If those aren't apparent then an alteration to the number of winds would probably have been the most likely possible change to alter the spring characteristics...

Am I correct in saying that all of this is a theory only or has one of these other springs turned up and been examined to determine any difference?....

We obviously have to theorise to come up with plausible explanations but I'm always conscious that at some point the theories become 'the facts' without any physical substantiation, a bit like canvas saddle covers (for desert use)....That was a good example of making the theory suit the existence of the actual covers...

In this case is all we have a different part number for a fork spring combined with the fact we don't definitively know why the forks were lengthened by 1/2" ?....I'm just playing 'devils advocate' here as a cautionary note before we all sit back and decide we've solved that one....

Getting back to the original post I think the later forks would be the ones to reproduce, purely on the basis that a larger number of bikes were fitted with them and there would potentially be more customers for that type....I still laugh when I think about the battery boxes I made...Initially they were all 1944 and they all sold on that basis. I then added 1940 boxes after many requests and ever after I often didn't have the 'right one' to sell...So, personally I'd caution against doing both types, at least initially when sales are important to recover costs..However, if you plan to make them to order a half inch alteration to the lower leg tube length would then be a practical proposition ....Ian

email (option): ian@wright52.plus.com

Many good points raised Ian, and I don't want to fall into those traps again if I can avoid it. I already make various parts with more than ten versions!

I was looking at wheel bearings yesterday as the worms began to appear. I guess bearings supplied with the relevant spacer would be the answer. And rear style spacers for the front might make sense if the newer bearings are narrower.

Back on topic, I'm still open to offers of a complete set of the longer forks. Although John has generously offered the loan of some, I get the feeling it will not be a complete set. That's not the end of the world as it will get me going.

I'm hoping that I won't fall into the version trap with these. There are three ways of replicating the castings. One is to make the tooling directly from a moulding taken of the original with machined faces built up and machined holes plugged. You always loose something this way due to combined shrinkages. Scanning the original and making a 3d model, but you can still have problems repairing the scan and the replication of faults or defects. The way I like to do it is the most expensive way and CAD model the part and machine tooling from solids.

This is especially helpful if cores are required as you can design them into the original model.

So even a simple fork bottom casting will have two mould halves and two cores.

After the casting is produced it will need machining and heat treatment.

To machine it tooling will be required to hold it.

Lots of work!

email (option): pes.sales@btconnect.com

Yes, these forks will require a substantial amount of jig work due to the irregular shapes of the basic castings...

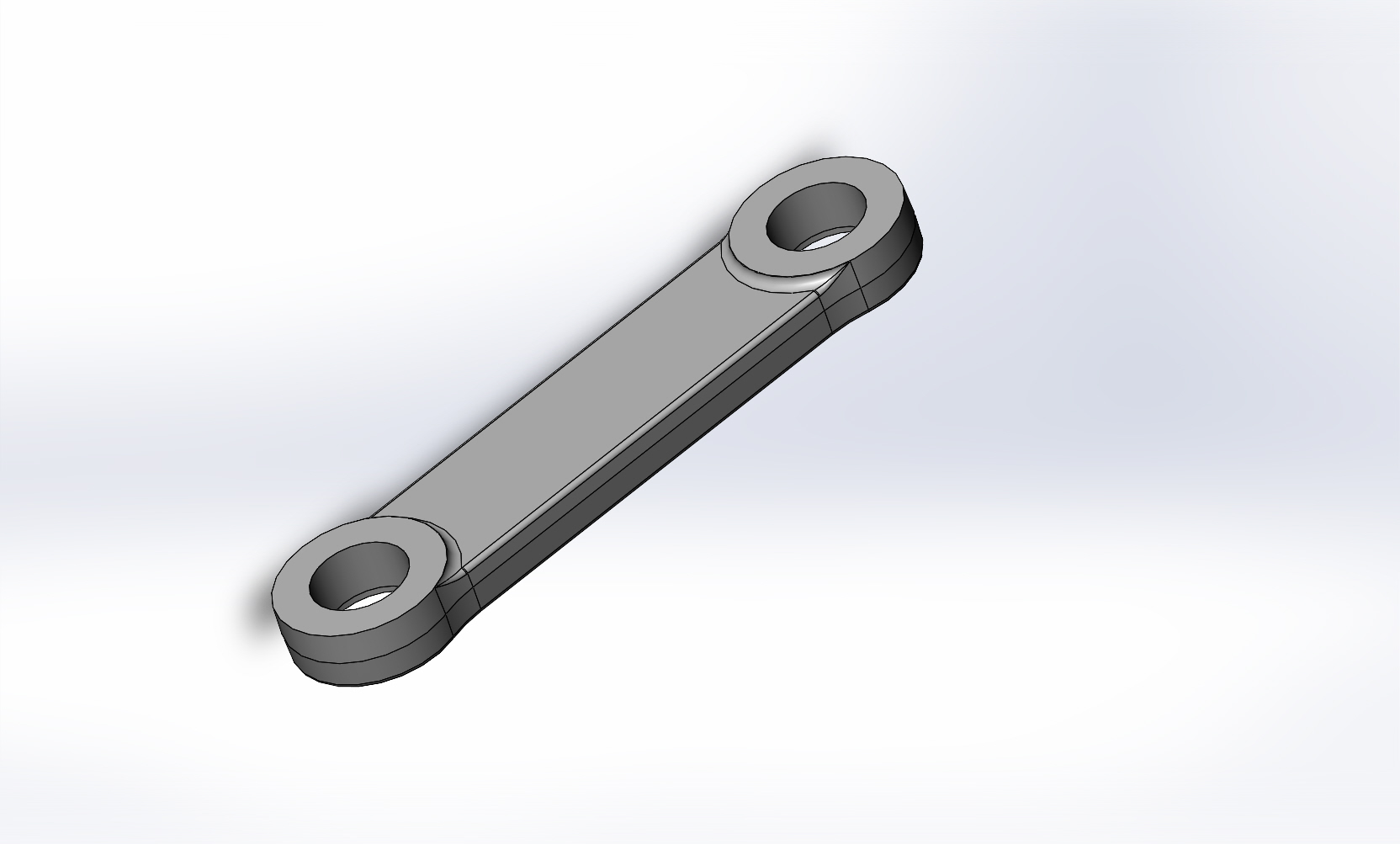

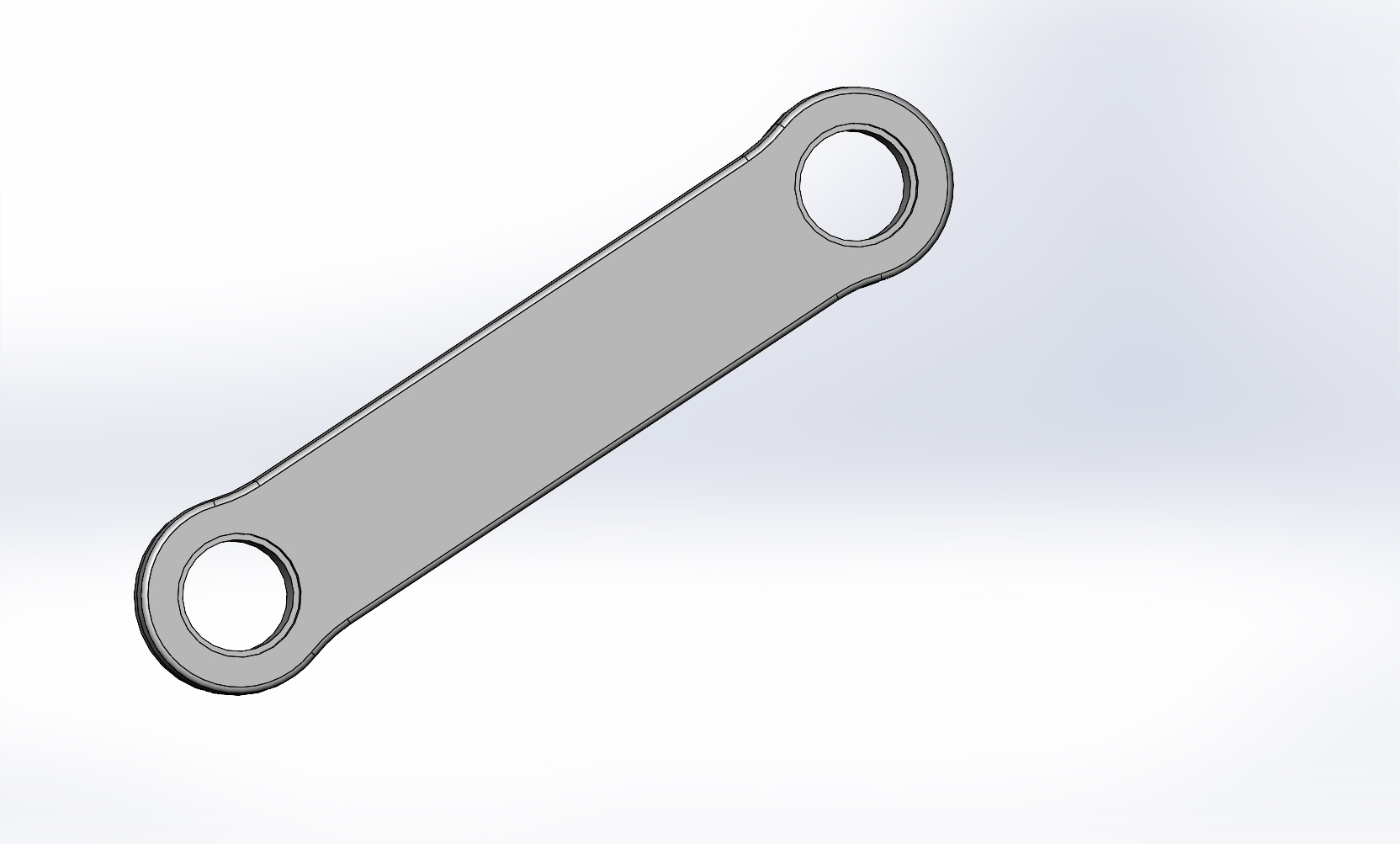

I'd also be inclined to look at the detail design in some areas, notably the side links and pins to see if manufacture can be made simpler with regards to the centreline accuracy between pins (which must be exact) and replacement of the pins when they eventually wear...I think this could be done without compromising the finished appearance of the forks....Perhaps, the spring mounting could stand some simplification, also without affecting appearance....

One definite shortcoming of the design from a purely practical everyday point of view is that each bush does not have it's own grease supply via a nipple...Some of the bushes share one nipple...In the event of uneven bush wear the grease takes the easiest route, ultimately starving the other bush of grease entirely...

Finally, if incorrectly adjusted on the link bolts, the sides (end faces) of the top and bottom yokes and the corresponding faces of the side links become badly worn...Ariel and Triumph forks have bronze washers fitted at these points, between the two components....This not only provides a 'sacrificial' component to reduce the wear on the major parts but it also simplifies the adjustment of the links, giving an indication of the pressure being applied by virtue of the free rotation, or not, of the bronze washers...Ian

email (option): ian@wright52.plus.com

Hi Ron

The bike arrived with solid type handlebar mounts as seen most war time M20

Balloon tank, 8” headlight, std levers ribbed bin valenced rear guard & later pattern carrier

It had a side stand mounting lug & no pillion footrest brackets

Sounds like a parts bin special - so a transition bike between early & mid to late war spec

Br

Jo’b

email (option): jonnyob1@googlemail.com

I'd also be inclined to look at the detail design in some areas, notably the side links and pins to see if manufacture can be made simpler with regards to the centreline accuracy between pins (which must be exact) and replacement of the pins when they eventually wear...I think this could be done without compromising the finished appearance of the forks....Perhaps, the spring mounting could stand some simplification, also without affecting appearance....

One definite shortcoming of the design from a purely practical everyday point of view is that each bush does not have it's own grease supply via a nipple...Some of the bushes share one nipple...In the event of uneven bush wear the grease takes the easiest route, ultimately starving the other bush of grease entirely...

Finally, if incorrectly adjusted on the link bolts, the sides (end faces) of the top and bottom yokes and the corresponding faces of the side links become badly worn...Ariel and Triumph forks have bronze washers fitted at these points, between the two components....This not only provides a 'sacrificial' component to reduce the wear on the major parts but it also simplifies the adjustment of the links, giving an indication of the pressure being applied by virtue of the free rotation, or not, of the bronze washers...Ian

The danger is some people want to keep the original short comings ???

email (option): pes.sales@btconnect.com

['The danger is some people want to keep the original short comings ???..']....

Possible, 'There's nowt so strange as folk'..:laughing:.

I guess some market research here might answer that question...Personally, better accuracy, material quality or other upgrades would be a no brainer in my book if the appearance wasn't affected..To a degree any user has already 'crossed the Rubicon' by using non original parts.....Ian

email (option): ian@wright52.plus.com

Just looking at the spring again.

The RAF outfit (66-5014 short fork) Lists spring 66-5150 (Draganfly quote this for M20 1937-45)

My 1941/2 parts list (66-5016 long fork) lists spring 66-5153 (Drags quote this for M20 1946-48) They show the same picture for both springs??

Ron

email (option): ronpier@talk21.com

Thank you all so much for your offers and help so far, just to let you know I have purchased some very rough almost complete forks.

Hopefully they will be good enough to work from. Don't expect me to be quick doing this as I have other commitments too.

One thing I think I may have picked up is that there seems to be a problem with threads stripping in the rocker links. Are these supposed to be threaded one side and a plain bore on the other? Are the links that are threaded through holes or threaded blind? All that I have seen have hex heads each side, does one side have a locking nut?

email (option): pes.sales@btconnect.com

The links are threaded (5/16 BSC) on the right hand side. Although I have seen the top links put the other way round with no adverse effect.

As I explained in another thread this week. The through bolts are just 5/16" rod with a nut welded/brazed on one end which is finished with a dome head. Ron

email (option): ronpier@talk21.com

Interesting discussion! My forks have the casting number 66-5018, which would indicate later in the war, I think?

Allan

email (option): allanmatchless@yahoo.com

Allen we've found that the number cast into a parts at the foundry is not necessarily the part number. The part number is for the finished part after machining and or assembly. Ron

email (option): ronpier@talk21.com

I’ve a set you could copy lm from Beverley East Yorkshire could drop them off

email (option): alandale468@gmail.com

Today a set of forks turn up in the post. Rough as I expected with usable repairs.

These have the length shown in the diagram of 17 1/8"

I've decided to reproduce them as I take them apart.

First horrors, the pivot bolts look home made. Though functional.

These are 3/8" diameter id this correct as I thought they should be 5/16" ??

15-5190 5 3/4" under the head to the end of thread ?? Thread being 1" long ??

15-5249 8 3/8" ?? ??

15-5247 8" ?? ??

Any help on corrected under head lengths would be good.

Should the head style be rounded or flat ??

Should the nut be 0.524" AF or 0.598" AF ??

email (option): pes.sales@btconnect.com

Hex size of the link bolts is a Whitworth size... .525" A/F...The bolts themselves are 5/16" diameter with a 5/16" cycle thread...Head form is a shallow dome...Ian

email (option): ian@wright52.plus.com

Thanks Ian, what I'd like to do is post some pictures to show everyone what I'm doing or planning. So the experts can shout "NO STOP"

I guess the pictures would need some kind of html address?

email (option): pes.sales@btconnect.com

:smile: :smile: I must have had my cloaking devise switched on? Ron

email (option): ronpier@talk21.com

Thanks Ron, and sorry. So much going on I'm getting lost.

email (option): pes.sales@btconnect.com

YES!!!!!!! This is awesome.

Please put me on the list for at least two sets.

Many thanks.

email (option): britool51@hotmail.com

I'd also be inclined to look at the detail design in some areas, notably the side links and pins to see if manufacture can be made simpler with regards to the centreline accuracy between pins (which must be exact) and replacement of the pins when they eventually wear...I think this could be done without compromising the finished appearance of the forks....Perhaps, the spring mounting could stand some simplification, also without affecting appearance....

One definite shortcoming of the design from a purely practical everyday point of view is that each bush does not have it's own grease supply via a nipple...Some of the bushes share one nipple...In the event of uneven bush wear the grease takes the easiest route, ultimately starving the other bush of grease entirely...

Finally, if incorrectly adjusted on the link bolts, the sides (end faces) of the top and bottom yokes and the corresponding faces of the side links become badly worn...Ariel and Triumph forks have bronze washers fitted at these points, between the two components....This not only provides a 'sacrificial' component to reduce the wear on the major parts but it also simplifies the adjustment of the links, giving an indication of the pressure being applied by virtue of the free rotation, or not, of the bronze washers...Ian

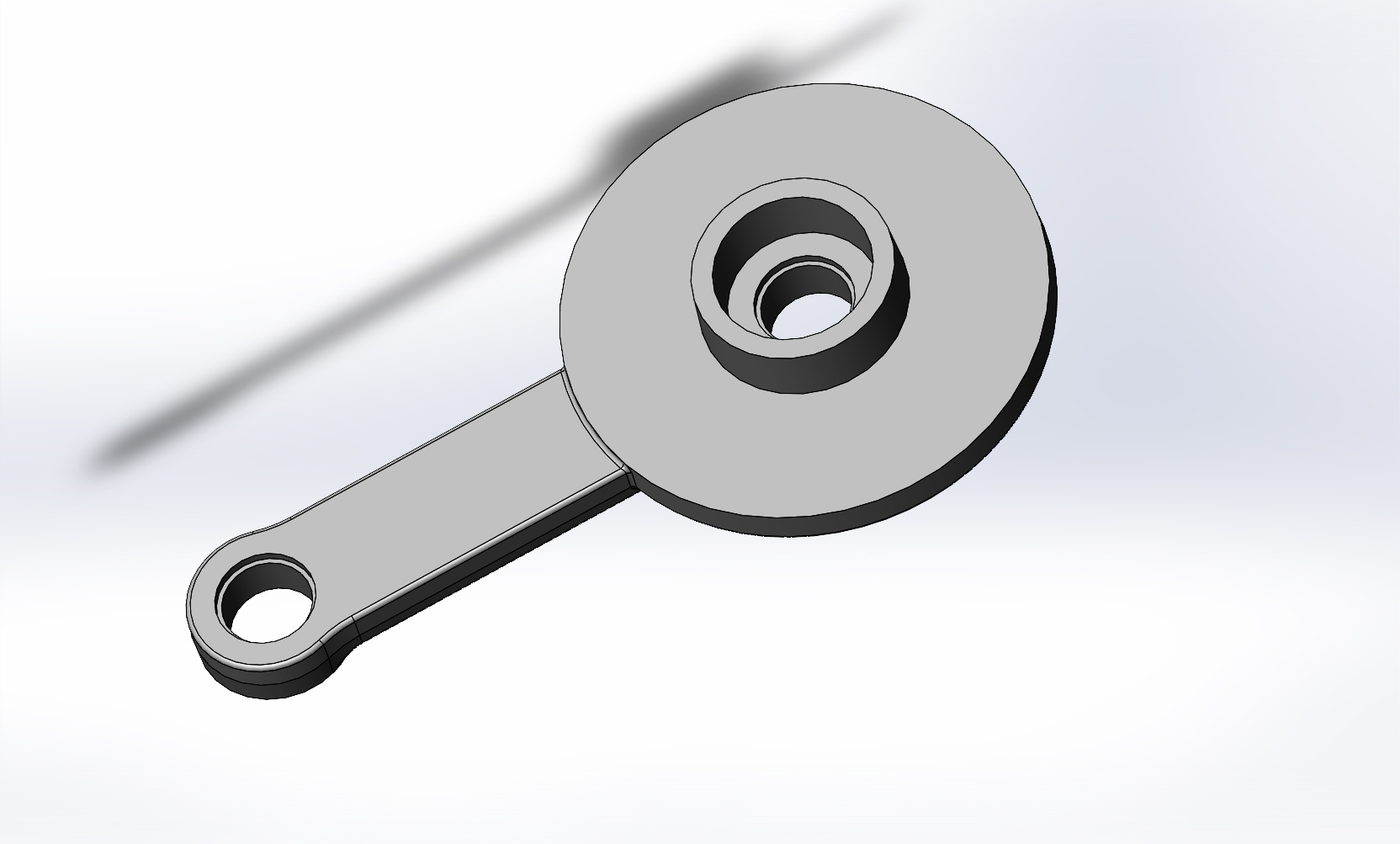

Taking notes of your points raised about the thrust washers, I have designed a bronze washer with an o-ring seal on it's periphery 1.7mm thick. This should stop the ingress of water and road dirt. After all most grease is not waterproof.

As for the links I think it would have to be a steel casting with hardened flanged pins pressed into it. This way the pin should not be able to detach. The case hardened pin and good quality bushes should outlive most of us.

Another couple of hours grinding left, so I might have the moulds drawn up this afternoon.

email (option): pes.sales@btconnect.com

Pressed in would be easiest though screwed in appeals from the replacement point of view...I haven't looked at the dimensional limitations with the latter though...

I don't think a casting would be strictly necessary...Without the pins three of the links would virtually be a flat plate so something CNC machined from solid would do the job I'd have thought...The exception is the damper link plate which again, I haven't looked at with a view to replication but is a more complex shape...Ian

email (option): ian@wright52.plus.com

If I was only doing a set for myself I expect I would just machine from solid. If you want to fillet, radius and draft angle it as well it's lots of work. In my mind without going to that trouble most billet stuff looks nasty.

So some quick models to make patterns from. I'll mask the through holes and machine them from the casting.

https://www.facebook.com/photo?fbid=1706326372873034&set=pb.100004870631985.-2207520000..

https://www.facebook.com/photo?fbid=1706327979539540&set=pb.100004870631985.-2207520000..

https://www.facebook.com/photo?fbid=1706328489539489&set=pb.100004870631985.-2207520000..

Lets hope these work!

email (option): pes.sales@btconnect.com

Hi, Just a comment on the fork lengths. The BSA M range had also 20" front wheels, and in the case of competition M24's possibly 21". This may account for the shorter forks. When I was racing an M24 in the 70's various people used to come for a chat in the paddock. One mentioned that when the M24s were used in the ISDT Fred Rist tried various fork link lengths to try to improve the steering. Nothing worked particularly effectively.

Please could I also remind people who are rebushing forks that there must be holes through the bushes aligning with the grease nipples so that grease is forced between the bush and the link. I have just examined a very worn steering stem where the bushes were not drilled like this so no grease got through to where it was meant to be.

Cheers

Pat

Just posting these again hoping they will be easier to view. After having a html refresher course via my IT expert.

email (option): pes.sales@btconnect.com

Does any have the dimension for how much pin protrudes from the link?

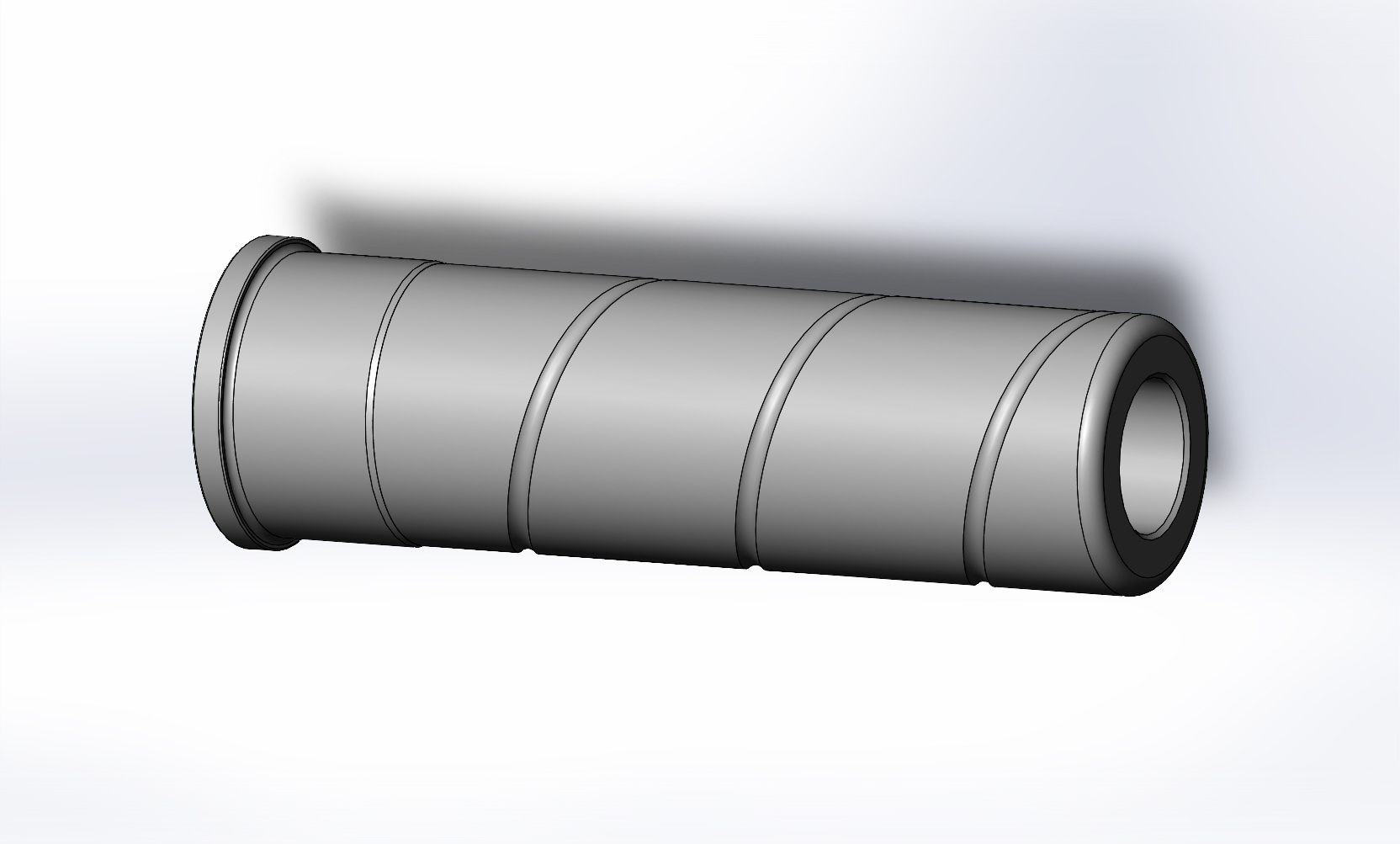

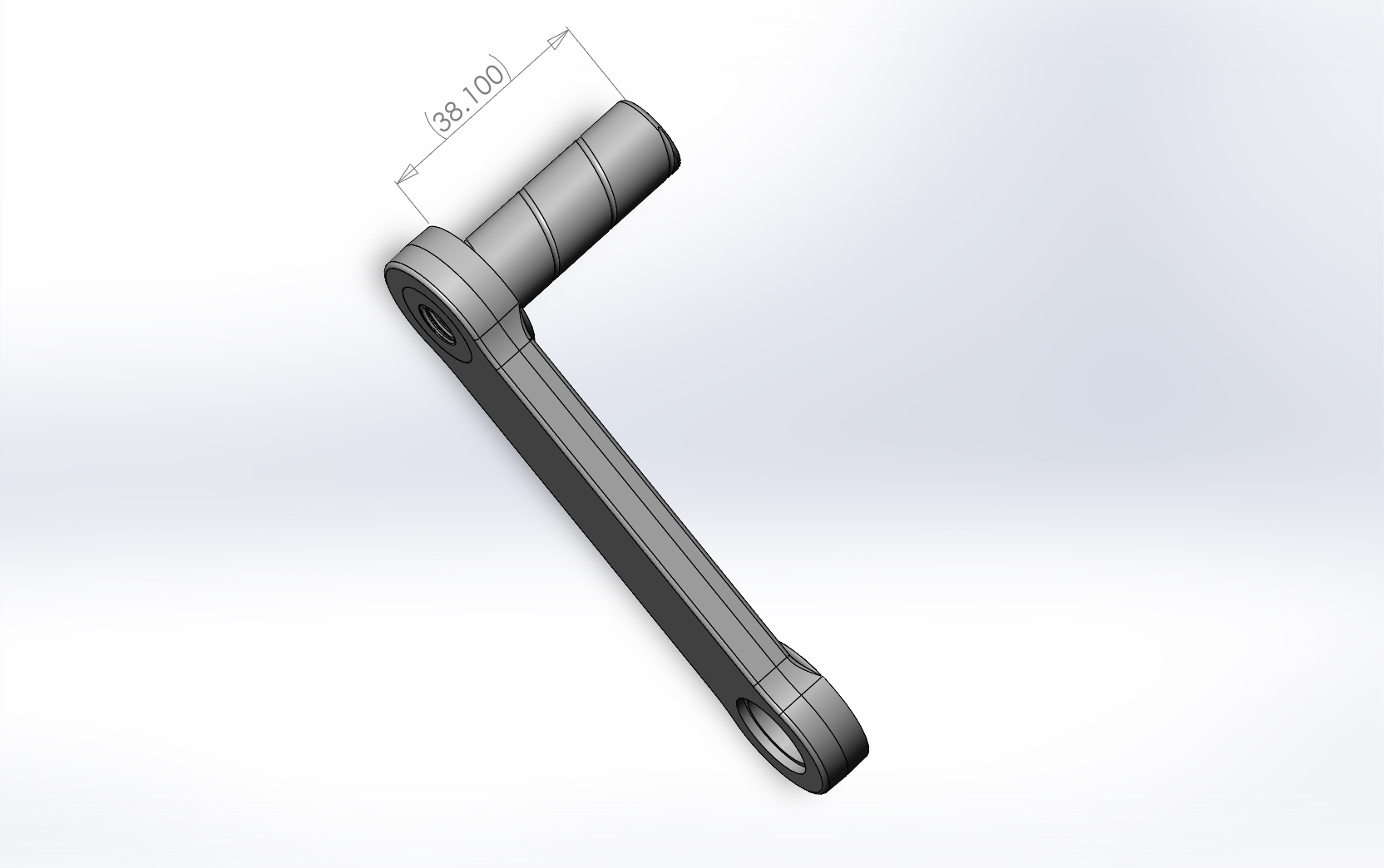

Below is my solid model of the the link pin I propose. It will be case hardened and ground before being pressed into the link. Due to the grade steel used it should out live it's new owners.

email (option): pes.sales@btconnect.com

I'll measure one tomorrow if no one beats me to it....Ian

email (option): ian@wright52.plus.com

The ones I have measured are all different en vary between 37 to 40 mm, protruding from the link.

The step you have drawn on the end of the pin seems very clever to me as the link can't come off when fitted :+1:

Personally I doubt if only a pressing in a casting will be strong enough for long time service.....but that is just a feeling..:relaxed:

Think these links and pins are one of the most stressed parts of the whole bike, especially the lower ones....

Good luck, nice project! BR Michiel

Pressing in the pins shouldn't be problematical in terms of reliability I'd have thought as long as there is sufficient 'fit' between the link and the pin, although the links themselves are fairly narrow...Both the outer diameter of the shoulder and the pin diameter itself would need to be a press fit into the link because of that fact...Ian

email (option): ian@wright52.plus.com

I seem to remember when Henk remade his link pins, he silver soldered them in. Ron

email (option): ronpier@talk21.com

Thanks Michiel, I'll go with 1 1/2" then (38.1mm)

Ian, as mentioned the pins will be case hardened and tempered to a specification I've been using for many years.

The links will be cast in a medium carbon steel and tempered to a condition I know to be very tough.

I think the car will know you've hit it before they fail!

The pins are not expected to be removed and it would be foolish to try.

Just for entertainment, a pin pressed into a link.

email (option): pes.sales@btconnect.com

I think it's Michiel who may have doubts about the method....I have often thought this would be a better way than the originals for the reasons outlined in my earlier post, namely better materials, better accuracy and easier manufacture...

The 'proof of the puddings in the eating though'. I guess there's a number of test pilots who can confirm it's not always right first time off the 'drawing board'....

In one of my jobs I was part of a four person group who's job it was to design and build special purpose attachments for automatic lathes so they could carry out 'non standard' work....That always involved 'tweaking' of the original idea over a period of 'tryout' running...In this case though I think the principle is well established and shouldn't present problems.. Ian

email (option): ian@wright52.plus.com

Unlike many other girderfork designs the BSA fork has separate links with no connection to each other and there for the position of the fork in line with the yokes has to rely for a great part on the protruding pins of the special BSA links.

Think the pins are subjected to a lot of different and strong forces, especially when cornering with a sidecar fitted... That is why I think only a press fit might give way in time.

They used very good quality steel on the prewar BSA's... if a simple press fit for the pins would do the job I wonder why they didn't do that than....

Saying that, I do know nothing about these modern casting materials and how hard you can press the pins in without cracking.

Anyway, you seem to know what your doing, Mark, good luck! :+1: :+1:

It's interesting when reproducing a product to try and imagine why it was made a particular way. I've never understood why an account gets put in control of a business. Many I have met are not good enough with numbers to be an engineer. To this end the price of production is more important than it should be.

The original method of producing the links is cheap once you have tooled up for it. The down side of this single piece construction is that the bearing surfaces remain relatively soft. But good enough to avoid any warranty claims.

I guess I'm going into overkill with my production methods, but we do a lot of parts this way.

My biggest fear would be the links popping of the ends of the pins, hence the flange.

The pins will be to the same specification as I make my gearbox shafts, they have proved to be very good.

So we are left with the bore of the link stretching.

This to some extent will be left to heat treatment, but in reducing it's ability to yield will increase the chance of cracking.

If it became apparent that the links were stretching and loosing grip on the pin after making them as tough as I'd dare, the next step would be to oversize the ends of the link. This would change it's looks.

If this unlikely event were to occur, I would recall the links supplied and replace them.

As to modern metals, I'm not over impressed. Unless you use remelted steel stock where they control the alloying elements more precisely your never really sure about what you are buying. I only use certificated materials from well known distributors. That said you can feel the difference even down a length bar when your pushing the machine hard when cutting it.

What has changed is heat treatment, and if you can find a subcontractor that cares about what they are doing it makes a big difference.

So I'm afraid you'll have to wait a while now for me to get the first sample castings made. Don't worry, if it all goes wrong I'll tell you.

email (option): pes.sales@btconnect.com

Just in case you were all thinking this was just another "pie in the sky" idea. The moulds for the links are now finished and will be sent to the foundry in the morning.

email (option): pes.sales@btconnect.com

Thanks Mark for your willingness to include everyone in this. I hope it pays dividends.

Thanks

email (option): cbhaws@verizon.net

I Mark,

I'm not an M20 owner, but I have to say I'm looking forward to Seeing the results.

And when you decide you want to venture out onto other similar products, there's a definite shortage of early war Triumph forks........

🙂

And non WD type Norton Webbs as used on vintage bikes and Inters, but again, so many different variations.

Low volumes, the amount of money that's required to be invested 'up front' to produce something and peoples uninformed assessment of the actual costs are the enemy of replication in truth...

Not unreasonably, many people these days are totally unaware of what low volume manufacture costs...

The benefits of scale don't really apply to classic bike parts so the low volumes must be offset by producing a part that can be made using relatively cost effective manufacturing methods, a limited number of separate operations and thus modest cost inputs...The more complex the part/assembly the less possible it is to produce it at a price the market will stand...

Also, in the case of a high cost part the finished machine has to have a value that can absorb such a cost without tilting the cost/benefit calculation for the purchaser way off kilter....For example, a £1000 pound set of forks isn't going to sell to someone who has a bike that's worth £1750 on completion...To purchase them would virtually guarantee an overall loss on the project..It's no coincidence that an examination of the most expensive parts on the market reveals that as a rule they are manufactured for the machines that have the higher market values...I bought many top quality and expensive parts for my recent Gold Star project but was still able to build the bike at a cost that would be, at worst, a break even point...

When I looked at making M20 cylinder heads what I found was a relatively high investment up front to produce a batch, a reluctance by many to use even a perfect replica (which immediately reduces an already small market) and a price expectation that didn't reflect todays production costs....I conducted a 'market survey' amongst M20 owners throughout one summer and it soon became apparent it wasn't going to be a viable project...

To date no mention has been made of the potential likely cost of replica forks and I'd imagine Mark isn't far enough into this to have made that calculation yet but don't expect to buy them for the price of a good second hand set, it can't be like that.....Ian

email (option): ian@wright52.plus.com

Thanks Ian for pointing out those facts, what we do is not a get rich quick scheme. We could legitimately register a a charity!

This said we often see parts seriously over priced, After all a Gold Star is only a posh M20 ;) The parts should cost the same to produce.

Funny you mention M20 heads, this a part I'v been (not) working on for a few years now. As you say a virgin pattern is expensive to make for what it is. I'm going down the copy pattern route with this to start with. Should work out cheaper than a well used head.

One thing that has shocked me is the price of replacement oil pumps. We have a few pumps underway at the moment. The B50 will be first and it close to completion, the internals sold before we finished the body. The bottom of the body will replace the the B44 and like. An extended bottom body becomes A65 and A10. Many of the gears can be used in the M20/Gold star Pump. We have made the top before, the rest is so simple it could be made while you wait.

As you mentioned will it sell? Who cares, we've been around a very long time and everything sells if you wait long enough. If it sells slow we'll be reluctant to make more.

Making commissions for others can be dangerous. Often we produce prototypes and hand out samples for testing and never hear anything again.

It will make sense for for someone to try a set of the links before I make them in larger numbers. They should be a direct replacement for originals. Finding someone who rides there bike regularly might be harder than the production. My bike is too far away to consider that.

The only other thing to mention is that non of our road going cycle parts are covered by insurance as it would be prohibitively expensive. It's all sold "For display purposes only"

That said the materials used will exceed originals in strength.

email (option): pes.sales@btconnect.com

Took the opportunity to run of a few link pins. They need a second op. and heat treatment before finally grinding to size.

email (option): pes.sales@btconnect.com

That looks already nice mark!!

Castings cleaned up, ready for heat treatment.

email (option): pes.sales@btconnect.com

That looks good

Hi Mark,

Had I known, I'd have had Bastiaan send you the NOS set I just bought from him!

Such is life mate..... Sorry I didn't know.

GORGEOUS WORK!!!!!!

email (option): britool51@hotmail.com

Just a small part, but I'm still at it. Not related but a rear sprocket spindle picture is also included.

email (option): pes.sales@btconnect.com

How long does it take to machine that spindle?

Not very long Ian. The two milling ops are down as 2 minutes each including handling. I need my wrist slapped for the turning op as I forgot to note the time.

email (option): pes.sales@btconnect.com

Thank for that Mark. In a previous life I was an Auto- Setter I used to run nine machines, a job long gone now with CNC.

I worked as a Big capstan setter operator, machining stainless castings once Ian. They had Wickman multi spindle machines there that women ran at night because they were so noisy. They fascinated me. I hate doing production work, so at PES we play at engineering just making small numbers of bits to keep your toys working ;)

email (option): pes.sales@btconnect.com

['In a previous life I was an Auto- Setter I used to run nine machines, a job long gone now with CNC...']

I did my apprenticeship with Brown and Sharpe and as part of that worked on their auto section for a couple of months...Back then they built a range of autos and also the first NC machining centres...It seemed like a miracle at the time when the first cabinets were produced that allowed the machine to do radii...How times change...Ian

email (option): ian@wright52.plus.com

I had Brown and Sharp, Bsa, Index and Peterman this was a multi spindle machine.

Yes I'm still doing this. Some brackets I had cut out.

email (option): pes.sales@btconnect.com

More fork parts,

15-5249 Link bolt, bottom front, 8 3/8”

15-5247 Link bolt, bottom rear, 8”

15-5190 Link bolt, top, 5 ¾”

Made from High tensile EN24T steel. The Nut is fitted on a tight thread, before being Nickle Bronze welded before machining a dome.

email (option): pes.sales@btconnect.com

Soooo nice!

Almost tempted to buy a M20 wreck just to fit one of these...ha!

Thank you Vincent, but I'd recommend leaving things alone if they are working.

They will be zinc and clear plated before being supplied.

I had a go at straightening the ones from my NOS forks and was shocked at how soft they are! When I try to straighten the links I wonder if they are soft too?

email (option): pes.sales@btconnect.com

The bolts don't really have any reason to wear or structural purpose. They are simply to keep the links into their bushes and allow a tiny bit of end float. If the bolts are tightened too much the links will wear into the forks/yokes. Ron

email (option): ronpier@talk21.com

This weekend was supposed to be for more building work on our works extension. Weather put pay to that.

As the Milling machine was empty I thought it was a good idea to make the tooling to machine the fork links.

The first job was the straighten the links, it might have been a better idea before sending them off for heat treatment. Though they could distort during heat treatment. You never know what horror will come back from heat treating.

The reason beyond the obvious for them to be straight is that when clamped in the jig they will not bend. Being spring like the parallelism of the bores will be lost.

So as Anita was machining the links, I was on straightening duty and pin pushing.

Despite our best efforts the parallelism of the pins wasn't perfect. More tweaking required.

Even though these are made to tighter tolerances than would have been achieved by BSA, I feel that these are best supplied in matched pairs.

Also including our high tensile bolts.

This way we can be sure when we supply links, we'll know they look at each other before shipment.

The unthreaded link should slide easily on the bolts as shown in the picture below.

we haven't machined the lower links yet as more tooling needs to be made, but it is progress.

Having case hardened pins and tempered links, these should give a stiffer feel to the bike.

Also have a longer service life than the originals.

The top link set will cost £120.00ukp

email (option): pes.sales@btconnect.com

The top links didn't play as well as the bottom ones. 15-5239 was a right pain. Firstly to straighten, then to jig. Not forgetting another jig to machine the other side. There was nothing I could use as a datum for all axis, so the pin bore has to be clocked up for each one.

If these links sell, I think I will redesign the moulds to make life easier later. At least I have a viable product and not a box of scrap.

I don't have a price for this set, but it will be a bit more than the bottom ones due to the extra work.

There should be 6 complete sets in a couple of weeks once the bolts are plated.

email (option): pes.sales@btconnect.com

Mark in your last post, have you got your top and bottom mixed up? Or maybe it's me?

Ron

email (option): ronpier@talk21.com

Thank you Ron, at least someone knows what I'm doing. Yes this last set are the bottom set.

email (option): pes.sales@btconnect.com

Sorry everybody, just double checked all the numbers again. Not only can I not tell the bottom from top I can't add up.

So..

Upper link set with bolts and nuts £144.00

Lower link set with bolts and nuts £176.00

Mark

email (option): pes.sales@btconnect.com

Bolts finally back from the platers,

So upper and lower link sets are on the the web site now.

Also the link blots.

https://pesltd.uk/?product=15-5239&ptno=15-5239

https://pesltd.uk/?product=15-5241&ptno=15-5241

https://pesltd.uk/?product=15-5241&ptno=15-5241

https://pesltd.uk/?product=15-5249&ptno=15-5249

https://pesltd.uk/?product=15-5247&ptno=15-5247

email (option): pes.sales@btconnect.com

Hi

Could you please upload a pictures of your battery box made. I was searching for long period

Nadun

email (option): dhammikad888@yahoo.com