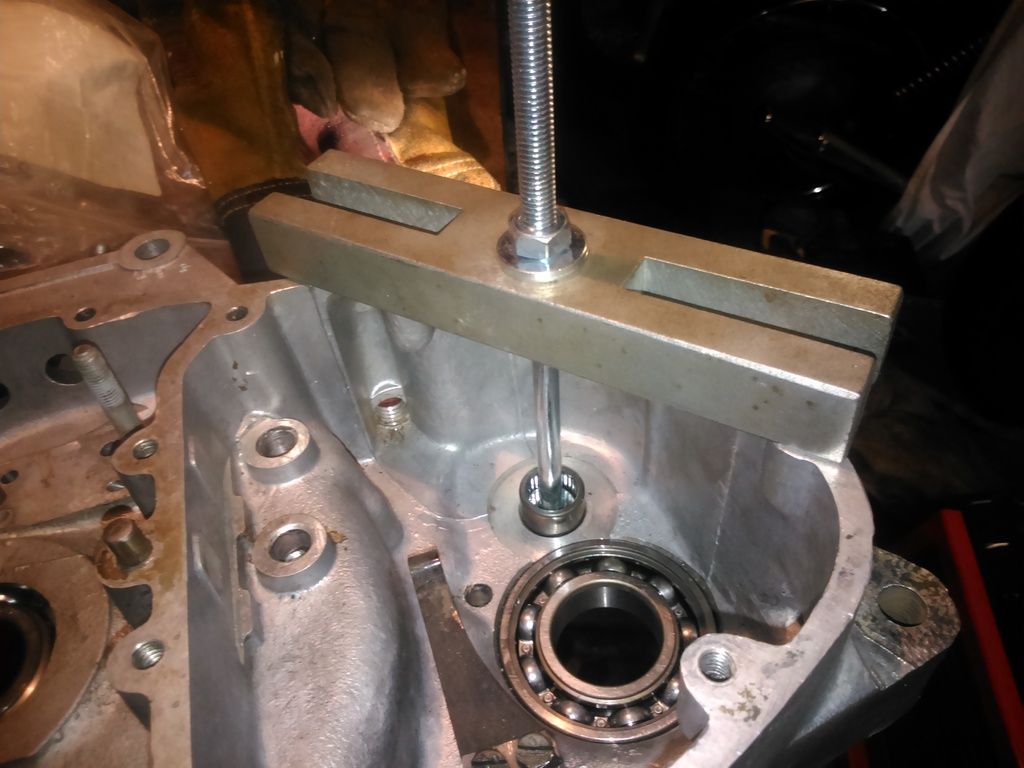

On this BSA engine I'm rebuilding, there's a small needle roller bearing on the end of the layshaft in the gearbox and there's no way of drifting it out. I've heated the case and tried everything I could think of to get it out, but it's tight. So I Googled how to do it, and got the best bit of info from one of the forums.

You get a coach bolt with a round head (luckily I had a long one left from mending the fence)and grind it to an oval shape, so it just fits the bearing one way, but is to big the other. Put it inside the bearing diagonally and rock it until the bolt is straight. Obviously it can't be tooo big. When it's straight you can wind it out like a normal puller. I couldn't believe how well it worked

email (option): horror@blueyonder.co.uk

That's worth remember for another occasion! I had a similar problem with a Royal Enfield main bearing. In the end I simply drilled two small holes and used a pop rivet as a drift. The new bearing seals the holes, which could be filled in with Araldite or something. Ron

email (option): ronpier@talk21.com

Drilling a hole behind this needle roller bearing was another method that someone suggested, but as I read down the page, the coach bolt idea was mentioned. I had my doubts it would work but I couldn't believe how easy it was. The trouble is I've ordered a bearing puller which still hasn't arrived and now I don't need it, but it is adjustable for bigger size bearings.

It was only £16.99 from these people,

http://www.manomano.co.uk/mechanic-tools/yato-pilot-bearing-puller-12-38-mm-1146344?g=1&referer_id=537135&gclid=CMbQ2KiLp8sCFQUFwwodLEULTA

email (option): horror@blueyonder.co.uk

As long as the claws can fit behind the bearing? Ron

email (option): ronpier@talk21.com

I think as long as they are wound out tight they should grip the bearing. There's no claws on the head of a coach bolt but it still gripped. I probably won't get chance to use it any time soon to find out

email (option): horror@blueyonder.co.uk

I use a Dremel and grind through the outer casing, usually there's not enough left when the CCM destroys its silly needle bearings - to extract by this method!

Problem with most bearing extractors is that they are made from monkey metal and are seldom strong enough.

Just don't try the 'fill with grease and punch out' idea - tried it when i was a callow youth and punched a hole though my Ariel arrow crankcase ....

If you do punch through - you can buy blind-ended needle bearings .......

Horror,

i'm just rebuilding my B25MX - needles look very good - do i replace or leave ???

RE B25 oil pressure - my Big End not very happy - rod to crank clearance is ~17 thou - it should be 5 thou - seems i'm losing oil/flow/press down the side of the rod.

Make sure when you get your crank ground they do not widen the journal - a good grinder won't - in my case i asked them to grind a definite radius between journal and web.

It was only £16.99 from these people,

http://www.manomano.co.uk/mechanic-tools/yato-pilot-bearing-puller-12-38-mm-1146344?g=1&referer_id=537135&gclid=CMbQ2KiLp8sCFQUFwwodLEULTA

Bad news about that pilot bearing puller you have just bought.

The original item has forged jaws on the puller and costs around $ 80 Aust.

If you got it from evilbay then at that price is it an oriential copy with cast jaws and will most likley break the first time you use it.

You can get split collets for quality slide hammers which will go under the lip and expand sufficiently to pull most Hoffmans.

Mine is a Sykes , about 50 years old, works like a charm.

Limbs are too precious to risk using cheap tools.

email (option): bsansw1@tpg.com.au

Thanks for the advice Trevor, it still hasn't arrived, so I may cancel the order.

Nig, I didn't get the B25 big end reground, it was in good condition without any wear at -10 thou. After the fly wheels have been machined all the way round to get the R&R rod in, it is too light for the balance factor. So I've had the crank balanced, they took a bit of weight off the top of the fly wheels and added some heavy metal plugs opposite the big end, so it should be quite smooth. I.m hoping the RSM high output oil pump will cure the oil pressure problems they had and I also found a rev counter drive for it as I like to know what the engine is doing. I'm still looking for a gearbox cluster as mine is badly worn.

email (option): horror@blueyonder.co.uk

horror - just watch out for rod to crank-web clearance.

Mine is three times recommended and it was not due to the crank grinder - but the tolerance on the rod.

I will get away with it for racing, but for something more durable ?

Read my tread on B50.org to see how my big engine is going pear shaped at the moment!

What balance factor did you use in the end - i've seen 65 and 68% ?

Even with a much lightened crank and a heavy rod + 75mm piston, i;ve not had to revert to heavy metal?

Hi Nig, I can't see how the rod to crank-web clearance has anything to do with oil pressure? The oil pressure relies on the output of the pump and the bigend shell bearing to big end journal clearance, which is probably 1 thou, a lot less than 5 thou..!!! so 5 thou or whatever it is, isn't going to produce any oil pressure as far as I can see. On most twin cylinder engines I've built there is a lot of side movement on the rods that isn't going to hold any oil back between the crank web. I've just checked mine with my dial gauge and it's 12 thou. I'm not worried about that at all, it doesn't seem any different from any other engine I've built. I didn't check the original rod so I can't compare it but mine hasn't been reground and I can't make the rod wider :-)

After everything I've read about the B25, it seems it has 2 main weaknesses, the rod breaks and the oil pressure was designed for a roller big end and wasn't good enough for shell bearings (the oil pressure release valve was a problem too on earlier models). So I've concentrated on these 2 faults, strong rod and high output pump. To me it seems pointless doing one without the other. You are revving your bike at max revs most of the time and without a rev counter you don't know how much stick you're giving it. I wouldn't rely on the standard oil pump. Also, the R&R rod has no oil hole drilled in it like the standard rod, so really you should get more oil pressure as it's not loosing it all twice per revolution, albeit only for millisecond.

I get my balancing done by Andrews Precision, in Bromsgrove, Worcestershire. It's dynamic balancing they do, so it's spun on there machine and done that way. They've done a few engines for me with great results. My Commando is very smooth at 6000 revs with no vibration at all. I gave him everything for the B25 and said balance it, he knows more than I do so I go with what he says. I think the final balance factor was about 56% which he says always works well for a single, we'll see. I notice the factory figures are 54% and 58% depending on which crank you've got. So it sounds about right.

email (option): horror@blueyonder.co.uk

thought it was 64 and 68% - but i cannot find the info i base these values on.

Balance factor depends on many factors - the 64(54) 68(58)% values depend on the frame - IOF or earlier non OIF.

The ES2 norton balance factor is very different for featherbed and pre featherbed frames - this i do know from vibratory experience

Regarding shell bearing side clearance - this determines oil flow through the bearing more that radial clearance (which should be 0.0005") - in a 'normal' engine with a decent lub system you can (and i have)run all sorts of radial and side clearance without problem.

The strange wear pattern on my shells has caused two people who's opinion and experience i value, to question the rod/web clearance - which i know is excessive.

she's getting rebuilt 'as is' but this time i will keep an eye on pressure.

As for balance factor - i need to calculate what i have and decide where i go next.

HORROR

Just had confirmed that you are correct with balance factor ;

1967 frame = 58%

1971 frame = 54%

I can understand that ideally the big end shells want to be evenly spaced over the oil holes in the journal so the oil flows to both sides. The oil holes should be countersunk to give a bigger pool of oil from the feed. I think this is more important than the rod sideways movement. Check your grinder has done this when he's done the job. I had never checked the side play of a conrod before as it's not something that is adjustable so there's nothing that can be done about it. It's either the right rod for the bike or it isn't. I haven't found any information showing a side play of 5 thou, where have you got this figure from?

One thing that worries me more than any of this is the lack of an oil hole in the rod. It states in R Ratio's book that without this hole you will get a top end seizure. I've spoken to an engineer friend, and he seems to think it's not required? I hoping that my SRM oil pump will fire out more oil than is needed and it'll fly everywhere..?? Maybe we should continue this off this forum as we've gone off topic

email (option): horror@blueyonder.co.uk

Sorry but rod to web clearance is important, very.

A decent lub system will happily compensate.

The oil throwing around in the engine is something else - all the B50 crankcase mods are to increase the amount of oil in the crankcase!!!!!!

On these engines it appears that the scavenging is TOO good?

Something i would not have thought possible - but all the experts out there say so....?

You will find that there's lots of experience and good advice for the B40/44/50 - less so for the B25 - everyone seems to think they are the same as the C15/B40/44/50 etc.

A case in point is my oil return from head problem - oh so easy say HP/PES - its the same head casting as the B44/50 ..... oh no it isnt!

Just proved the point with PES this morning - the b25 head casting has a lot less room for their mods.

Ok thanks Nig, I am putting all my faith in this SRM oil pump to solve these problems, more oil flying around has to be a good thing.

I'll e-mail you for more info on these mods as I can't seem to find the posts on the B50 forum. I must be writing the wrong words in the search,  Cheers

Cheers

email (option): horror@blueyonder.co.uk