I think the valve I use, that I posted a link too, is a good one or I wouldn't use it, we are all jumping to assumptions when we don't have any facts about this Norton twin or what the owner has done. I would like to know more, what valve did he use, did he check that the oil returned after fitting, what oil was he using etc.

A tap can be fitted but I don't like the idea, I have one on my Manx and I use one of those bright coloured curly wires for disc locks, as a reminder, but I'm still worried about forgetting. The Manx feed is too big to fit one of these valves.

On a Lucas K2F mag, the earth can be fitted to the oil tap so the lever grounds it when switched off, so the bike won't start, and a similar setup for coil ignition. But on mag dynos there is no earth cut out so I don't know a way.

email (option): horror@blueyonder.co.uk

I have seen and been involved with two trashed engines that resulted from the use of these valves...One, coincidentally a 'no expense spared' and very expensive rebuild of a Commando carried out by a good friend...

Regarding a magdyno, the high tension lead can be earthed...It's just a case of working out the connection (contact) at the valve end...

The beauty of a manual valve is that it is just about impossible for it not to function when the lever is turned...It is just a matter of introducing a method of overcoming memory lapses...

Any automatic system can fail to operate and in high risk industrial environments for example 'fail safe' is the only permissible option when designing systems...

In the case of a solenoid operated valve as suggested by Nigel it would have to be structured so that in the event of failure the valve remained open, not closed..Ian

email (option): ian@wright52.plus.com

Bummer! :-( I've just fitted one of those valves to my WM20 as she was just puking oil everywhere! :-/

The valve seems to have worked though, and, I watched the system working withthe engine running - oil was returning into the oil tank, which to my understanding means that it's doing it's thing properly.

Don't go scaring me folks! I've had my fair share of problems with my bike and the problems just keep on coming, I dont need any more :-/

email (option): fozzie001@hotmail.com

Ian,

The stainless type of valve you have fitted to your M20 will work fine if you have fitted it at the engine union. I have used one of these for years on my 16H and i do use the bike regular long and short journeys. I would not fit one to a bike that had a higher speed pump that requires a large volume of oil to be circulated to keep the white metal bearings from rubbing. The valve must put some sort of restriction in the line even when it is open that is why it may fail in a engine that requires a large volume of oil. But our M20s and 16Hs don't, and they have steel bearings.

It's all personal choice and it has worked very well for me. If you are worried about it take it out and it cannot be to hard to drain your sump after a long lay up. As i said in a previous post as long as its taking 3 to 4 weeks to drop half a pint i don't think there is much wrong with it. Remember in the past these bikes were used even day and had no time to sump. I will be leaving my valve where it is.

Tim W

email (option): t.j.walker@btinternat.com

Exactly Ian !

I would have thought regular oil changes and perhaps use a hi detergent diesel engine oil would stop any valve sticking .... ?

Perhaps RON's experiance was something other than the valve itself malfunctioning, there could have been something that caused bits to float around the system, which caused the valve to lock up ?

I must admit i keep to the KISS principle (Keep It Simple Stupid) and beleieve firmly in the 1st law of Engineering (if something can go wrong - it will, usually at the worst possible time - i.e. the YORK flood barrier!!!)

Yes, there is no doubt the valves may work fine in some applications...

For various reasons I have concluded I don't like them and wouldn't fit one but I don't claim to be the final arbiter on anything...I just take my part in the discussions...

'Pro' and 'con' opinions must be weighed up by the individual and if your conclusion is that they are a good thing, go for it and don't worry....Ian

email (option): ian@wright52.plus.com

I thought i'd shut up on this topic until .......

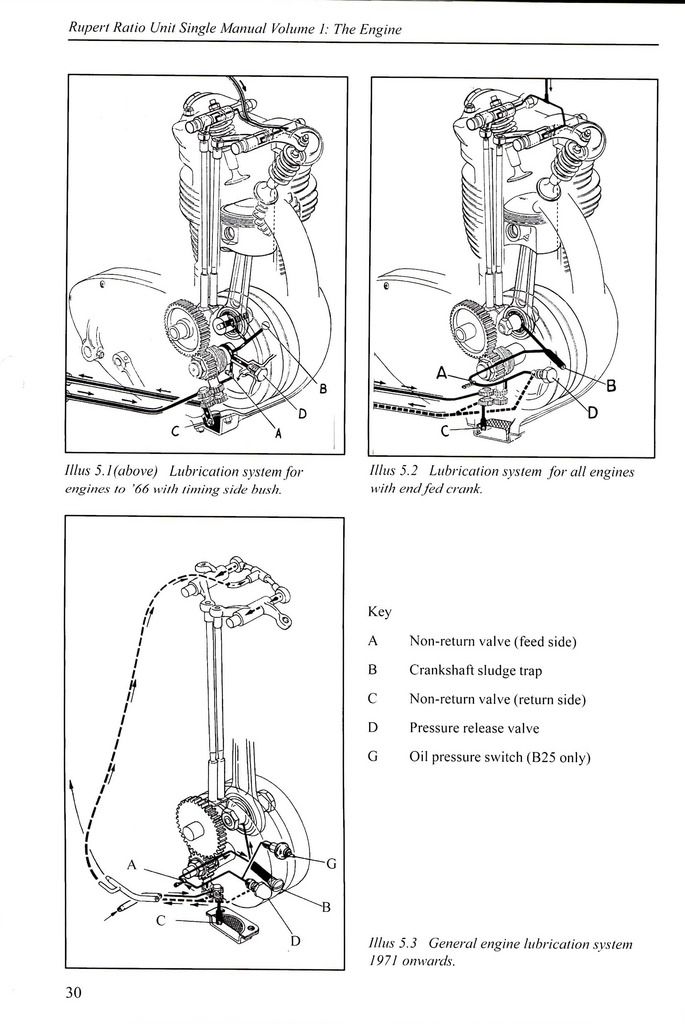

I'm fiddling with my 'new' b25 MX engine, and ..i forgot its fitted as standard with an 'anti wet-sumping' ball-valve/spring system.

So are all the c5/b40/b25/b44/50 variants ..... if BSA thought they could be reliable then no reason a retro fitted one - with the correct spring tension - shouldn't be, with clean oil etc.

That above being said, wet-sumping on B50's is certainly not unknown - but at least they 'fail' OPEN rather than closed (in fact when i think about it, i'm not certain how they could fail closed????)

correction - there's actually TWO - one on the suction side and one on the output side.

The latter i suspect is to hold oil in he crank for cold starting, before pressure builds for the big-end

Where are they fitted Nig..? I've got my B25 engine in bits but I haven't noticed a ball and spring. Cheers

email (option): horror@blueyonder.co.uk

Ah, thanks for saying about it, that saves me putting a valve in line, I've just had a look at Rupert Ratio's book and found it. I wouldn't have thought of looking up the scavenge pipe for a ball and spring. I guess it keeps the pump primed. The trick now is to make sure it works.

My new present to my B25 is the high delivery oil pump from SRM which I hope cures any oil pressure problem they inherited.

email (option): horror@blueyonder.co.uk

HORROR - my nice CI 1972 oil pump has now started to wet-sump - a bit.

The smug answer is to keep the oil clean, but i have (very) regularly changed the oil and ......

Anyway, it due to be stripped later this month once i hear back from the DVLA - so perhaps i will find something holding a valve open somewhere?

FYI - best piston to bore out a B25 seems to be a STD Yamaha XT250 piston - 75mm, this allows a spigot thickness of 2.5mm.

Just enough - assuming you don't want to bore out the crankcases ....

Also leaves the oil drain holes clear of the liner, so you don't need external drain lines (like a CCM).

Gives a 10:1 compression - MAX, though.

You do have to make 'top-hat' sleeves to reduce the piston wrist-pin holes from 20mm down to 5/8".

An alternative is a std MORGO 75.5mm piston (about £78 new) which has a 5/8" wrist pin as standard, but the compression height is lower - which probably nicely compensates for the crown 'hump'.

It does leave the spigot thickness a bit marginal ?

Thanks for the reassurances guys :-)

Now, just to iron out all the other problems... Ho hum...

email (option): fozzie001@hotmail.com

Grandpa's solution to the wet sumping was adding the oil tap to the engine feed line. It's been on the bike so long now it's just part of the starting routine.

I did something similar to Ian's suggestion with the bungie cord though, with attaching something obvious to the oil tap - as you can see if this pic.. :D

email (option): matthew.j.croucher@gmail.com