Hello guys,

I am tiered of gearbox dripping oil, ant allot of it,

And looking to open it and replace the bearing to a sealed type ones.

So just o be sure:

Which bearing should I replace with a closed type one and leave the inner side opened:

Only the drive side drive sprocket bearing for the mainshaft?...

Thanks,

Noam.

email (option): noam10@gmail.com

Hi Noam...Yes, just the large main gearbox bearing. (number 6207 2RS with rubber seals). The small bearing at the other end (LS7) is contained within the box so it doesn't matter if oil leaks through it...Ian

email (option): ian@wright52.plus.com

Thank you Ian !

Noam.

email (option): noam10@gmail.com

is it easy to change if the gears dont need repairing ie pull all the gears out in one big lump change the bearing and drop it the gear lump back in

email (option): roger.beck@node6.com

Or avoid all that mucking around and just use semi liquid grease!

Thanks guys !

Noam.

email (option): noam10@gmail.com

Hi Noam,

It's more than just bearing shields. No one in their right mind would make anything like a leaky gearbox fresh from the factory. These were expected to cover thousands of miles before a rebuild.

Fisrt of all, there is probably more that one screwdriver nick on the mating faces of the cases. Those can be flat filed out. Be careful though.

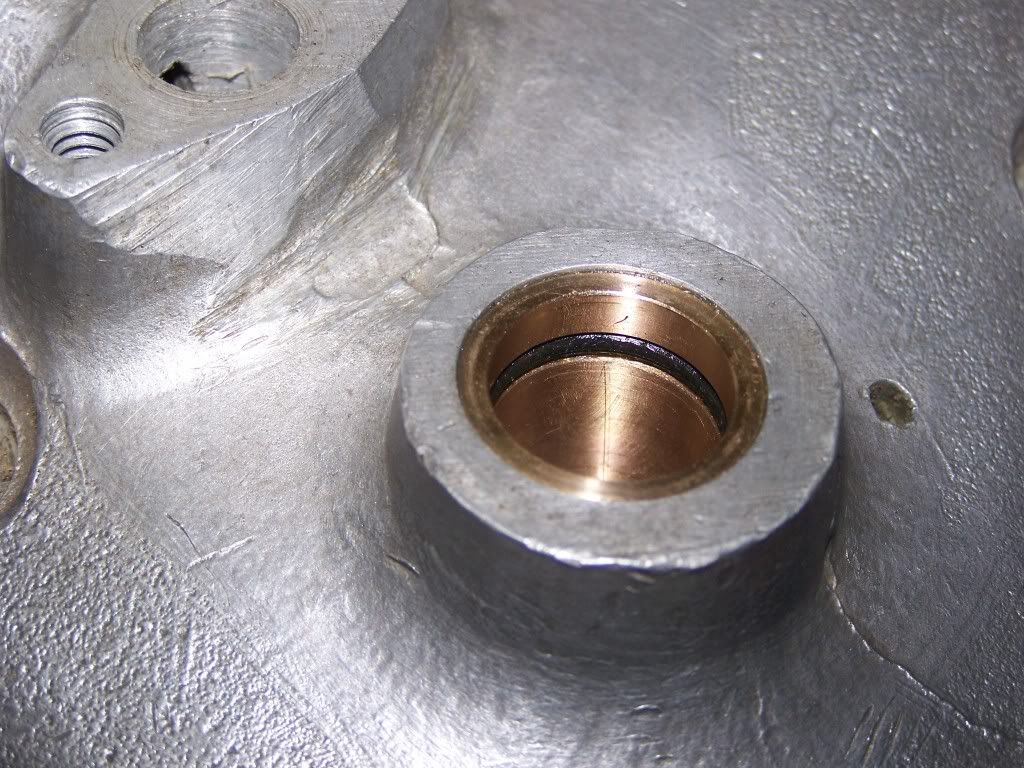

Then, the bushes can be worn promoting leakage. Brandon in S. Africa machines a groove in them to install an "O" ring which is quite effective.

Between the inner and outer cover, it is supposed to be dry, and that gasket is often neglected, leading to some seepage. I put a sealed bearing in the shifter side too.

The oil seal on the drive side can be changed without taking the box apart. That is a rather simple job, just time consuming as you have to take the box out.

Cheers mate!

PS: Great food you have over there. Thanks for the cookbook!

email (option): britool51@hotmail.com

Worth noting though that BSA were still selling a model with total loss lubrication for good couple of years after the introduction of the gearbox in that form & a bike with only occasional drips from the gearbox bushes probably still seamed like an upgrade from a spewing G14

BSA handbooks were still recommending checking gearbox oil levels at 300mile intervals well into the 1950's I'm sure they didn't think it was evaporating.

And I think Ian's post on a different thread explains why semi fluid grease wont work.

http://pub37.bravenet.com/forum/static/show.php?usernum=3155626639&frmid=16&msgid=1226367&cmd=show

Ron

email (option): ronpier@talk21.com

Therefore every Burman grease box is Knackered? Not so, have used liquid grease for 8 years!

on an M20?

email (option): Gasboy@btinternet.com

Hello all and thanks again.

I really appreciate your help on that.

I have 2 questions then, mainly fore Robb:

1 Can I order those bushing with the O ring?

2 The outer cover should be dry, but you pour the oil into it, don’t you,

And this is also the place where you check for the oil level, don’t you?...

Noam.

email (option): noam10@gmail.com

I agree Douglas. I also use semi fluid in my Burmans. But the grease still oozes out through the open bearings. So I also replaced those with the sealed type.

Just my way of doing things. I would now like to stop the oil that is dripping on my hot exhaust from the kick start bush on my CO....Frying tonight!  Ron

Ron

email (option): ronpier@talk21.com

I'm only expressing my views here based on my knowledge of the design and operation of the BSA M Series gearbox, including the method of lubrication. I don't have a similarly detailed knowledge of the Burman box which may operate perfectly well on semi liquid grease and I make no comment on using SLG in that application. It would seem unwise to me though to assume because something works in one gearbox it will therefore suit all types.

When considering the layout and method of construction of the BSA gearbox with regard to lubrication and where and how the lubricant is going to reach all the parts that require it, it is,in my opinion, plain to see why BSA specified an oil as the lubrication medium and not a SLG...

The lubricant has to enter the hollow layshaft and then pass through drillings in the shaft to lubricate the gear bushes and the shaft itself. There are also drillings through top gear and third gear and thier bushes to lubricate the bushes and mainshaft. The selector fork shaft and its bushes are located in the upper part of the gear case and also require lubricant...this is thrown up by the rotation of the gears on the shafts below it.

The gearbox oil also has to reach the outer cover to lubricate the gearchange mechanism and kickstart ratchet assembly and the smaller of the mainshaft bearings.

The filler plug is located seperately to this part of the box, in the main gearbox case, and the lubricant reaches the outer cover via a hole cast into the inner cover. The gearbox main bearing also has to be lubricated and additionally,the lubricant also has a secondary function of cooling the bearings and other parts.

Semi liquid greases have a much higher viscosity than a 40 weight oil, so as well as having poor 'flow' characteristics which will limit or prevent them reaching some areas of the gearbox, they also have the capacity to block the small drillings..thus preventing further lubrication altogether. I wouldn't think it was likely to find it's way up the hollow layshaft either...

Coming back to the initial subject of the thread..which is the prevention of gearbox leaks, in the case of the M20 this can be achieved by fitting a sealed main bearing. More minor leaks, which are really only 'cosmetic' can be eradicated by the fitting of O rings etc. where appropriate if desired.

It is therefore not necessary to change the viscocity or nature of the gearbox lubricant, which was selected by the original designers at BSA to suit the design of the box itself.

It's unwise in my opinion to make arbritary changes to specifications like this without considering the reasons for the original choices of the designers and thinking about possible consequences of any change that might be made. It is also necessary to think beyond the obvious..which in this case is a gearbox leak.

I therefore stand by my original statement, that in my opinion (and it is just my opinion) semi liquid greases are not suitable for the M20 gearbox...and further, with a change of bearing, are not even necessary...Ian

email (option): ian@wright52.plus.com

I like that very much Peter. I just need your address for when I next take the cover off

Ron

Ron

email (option): ronpier@talk21.com

ok i will ask what does CP mean the world is full of acronims

email (option): roger.beck@node6.com

Roger CP is just a model code. Burman seem to have used loads of these codes over the years. They must mean something to someone. Ron

email (option): ronpier@talk21.com

Corredction..

I see I was wrong.

Took another look and I see you fill oil to the main body.

Somehowe remimbered it was to the cover side..

nOAM.

email (option): noam10@gmail.com

Started the tear-down process today and it looks pretty straight forward so far if your transmission is out of the bike like mine was. After the outer cover is removed on the kickstarter and shifter side, you pull one pin and remove one nut to drop the shifter mech out as one unit. That gives access to hidden bolts. Two bolts and two recessed screws hold the inner cover to the tranny case. With the nut that holds the chain wheel removed, everything will slide out as one lump. Then you can remove the main bearing.

email (option): dgordon4@austin.rr.com

I replaced the old gearbox bearing by a sealed one as advised. It's not leaking anymore from this side now... but has started to leak from the gear change ratchet side. Not a lot but enough to be bothered.

Any tips?

Ciao, Daniel

email (option): drossi54@hotmail.it

Any tips?

Ciao, Daniel

It's my observation that if the gearbox oil level is a bit high, the overage will find its way out through the outer case k/start and gearchange shaftways. The issue seems to resolve itself as the tranmission oil "finds" its own level...just keep an eye on fill level through the fill/level plug; in my opinion, if you can see oil in the box through the level plug, all is well, even if it is a tad below "topped up".

Also, I did not pull the inner seal on my replacement output bearing...makes no sense to me to allow unnessessary contamination of the pristine new bearing from the inevitable gearbox fines. The bearings are lubed and sealed for life, for a reason...

Additionally, I tried the semi-liquid grease approach in a lazy attempt to avoid taking the time to install a sealed bearing. I can testify first-hand to Mr. Wright's observations; the SLG cannot get to all the points in the box where it is needed, most noticably the far end of mainshaft as it passes through the 4th gear bushings, the bushings run dry, and grind to powder in short order.

I did have a Royal Enfield Motor Mower with a straight-cut gear train to the blade and drive roller: SLG worked great in this application....

JDE

email (option): teladelujo@msn.com

Gear driven blade and roller?...and there was me thinking everything new was made better...Computer designed so it must be..

....Ian

....Ian

email (option): ian@wright52.plus.com

Thanks John. In fact I didn't mention that it has stopped leaking after a while. I didn't want to influence the answer. You are probably right. I will keep it under control like you are saying.

Ciao

Daniel

email (option): drossi54@hotmail.it

....Ian

....Ian

Other than the WDBSA site, it doesn't get any better than this.....

http://www.lawnmowerworld.co.uk/archive/royalenfield.html

Cheers,

JDE

email (option): teladelujo@msn.com