Hi,

again I need your help, maybe one of you had the same problem.

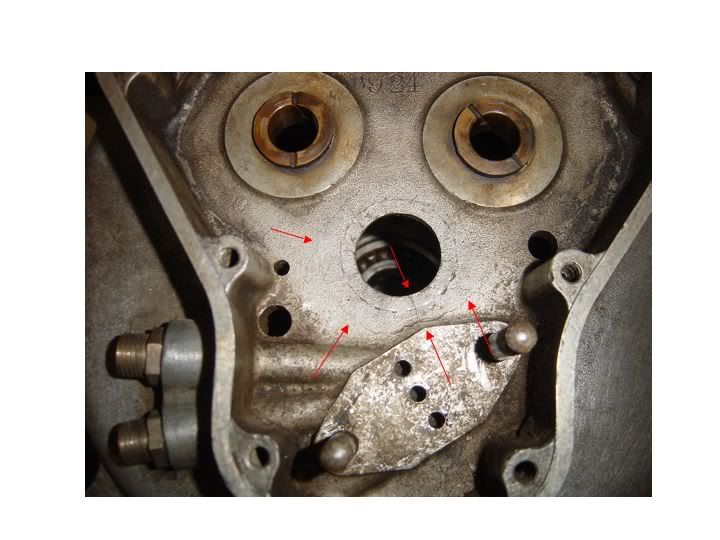

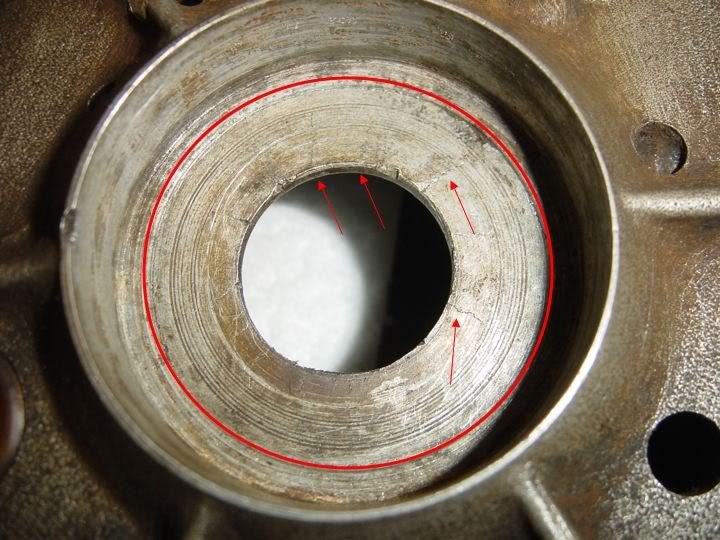

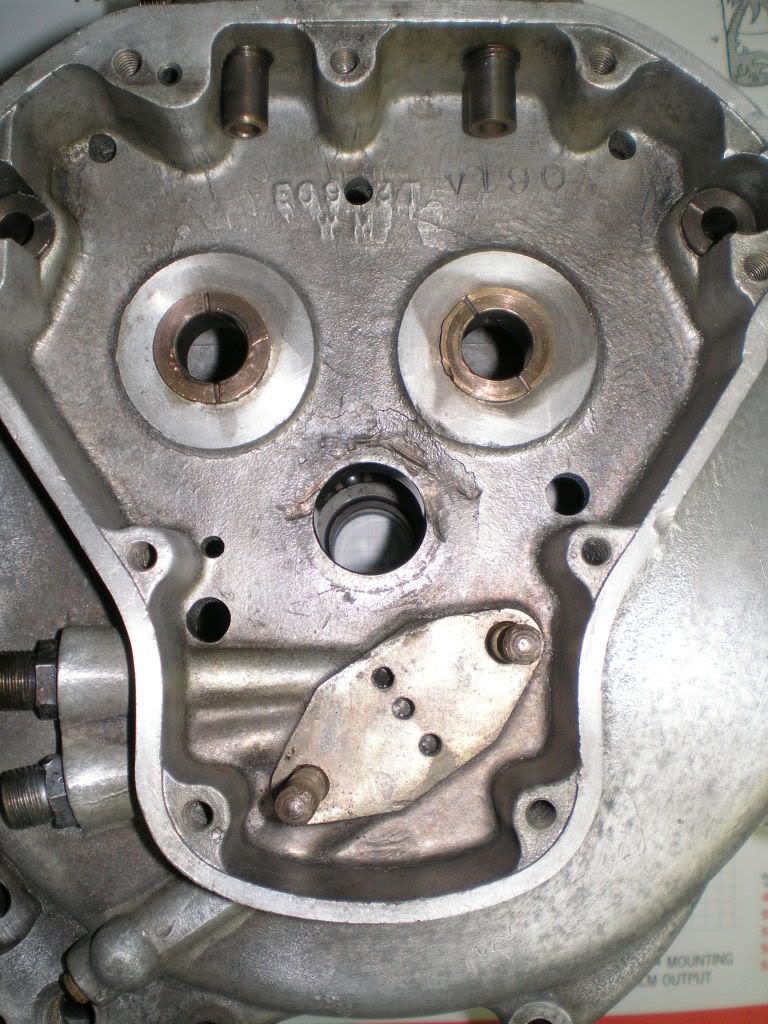

close to the bearing bracket my crankcase shows lots of fine cracks round the bracket. Better say inside the bracket, the adapter for the bearing looks fine, just the bearing cover. See Pictures. Shall I weld the cracks or remove the cover layer? Have seen this on another engine. See also picture. Thanks a lot for your opinions.

Phillip

Looks like the pics are not attachable???

I used a local path (pics on my PC) in the post??

email (option): phillip.thaler@gmx.at

Hi Phillip,

To be able to post photos you need to upload them first to a website like www.photobucket.com. Once uploaded there you need to copy the html code and past that with your forum post.

Henk

email (option): ahum@quicknet.nl

Hi Phillip,

We have a few real (Ian? Dave?) experts her on this forum, I guess that one of them should take a look at your crankcase.

Henk.

email (option): ahum@quicknet.nl

The damage that you're showing is very common on earlier engines and the later WD cases were machined differently to avoid the problem.

It is not an area that is subjected to stress or loads so I'm pretty sure that the damage is caused by previous owners trying to lever off the crank pinion. There is very little room behind for a puller.

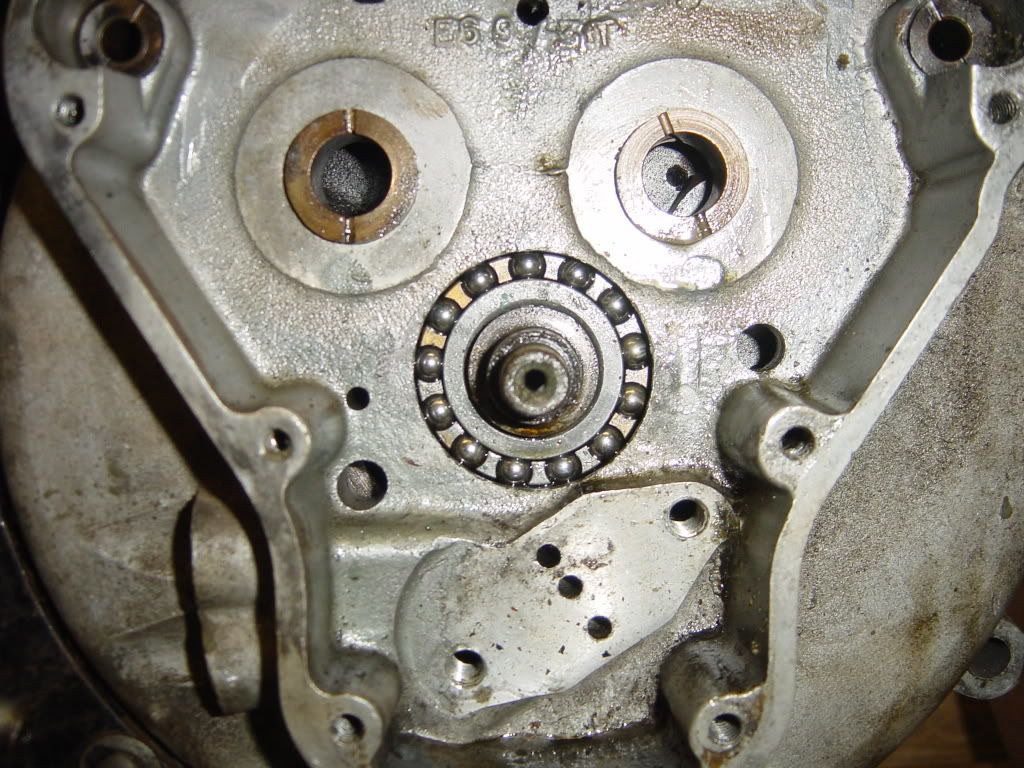

At some time around late 1940 (I'm not sure exactly and surprisingly enough, owners are not usually prepared to strip their engines to satisfy my curiousity !), Nortons increased the diameter of the through-boring to that of the bearing outer race.

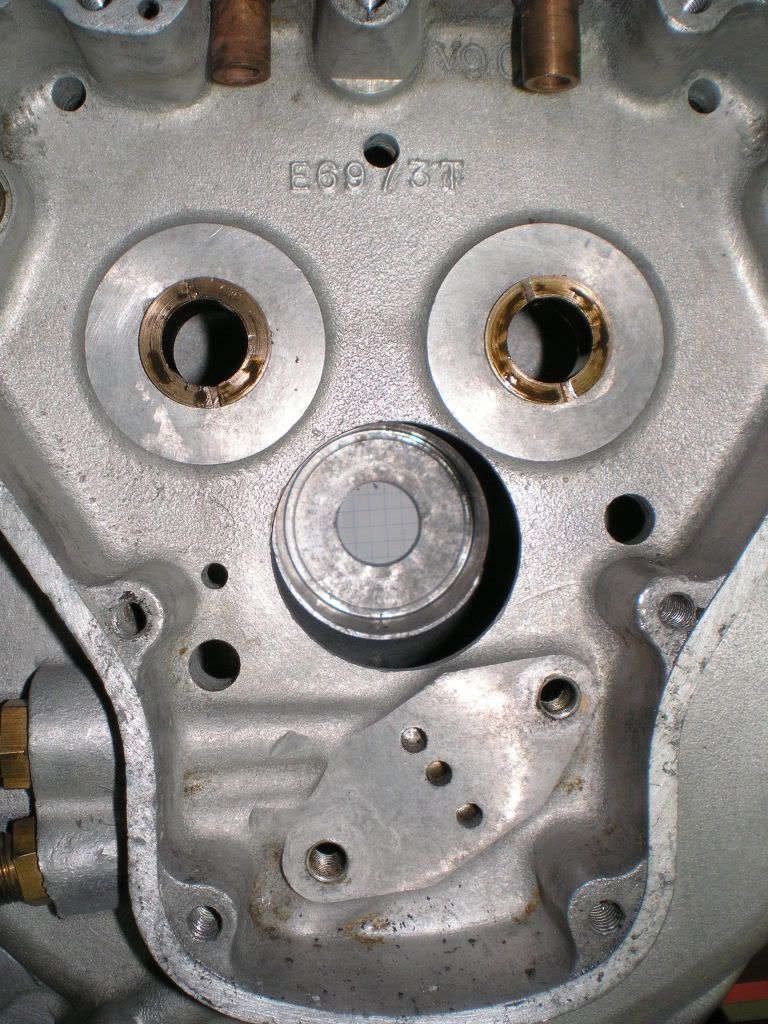

This is a New Old Stock crankcase which I'd guess from the casting dates from 1945 or so :-

If I were in your position (and I will be when I put my spare 1939 engine together), I would machine out the damaged area, leaving only that necessary to support the bearing outer ring.

It occurred to me that having a substantial opening and allowing the crankcase to vent easily into the timing chest might have consequenses for lubrication and engine breathing but we're not talking about a full-race engine here and there is no trace in the parts books of modified cases or covers - all parts remained interchangeable.

I've examined both types of cases carefully and can see no differences in the oilways or other details. There are several breather holes in the casing anyway so it probably vents as one chamber.

With any luck, modifying your cases to the form of the late part should be enough to clean up the damage. It's obviously not good practice to have a cracked edge close to a bearing housing so if it isn't enough, you may have to think about welding and re-machining but with all the attendant risks of distortion, that is an option to be avoided if possible.

This is a late 1940 case with the bearing still in place. It looks to be factory machining on the housing.

Hi Phillip..I am not totally familiar with the assembly procedures of the Norton..However, this problem sometimes occurs in BSA engines.

Usually it is the thin part of the bearing housing wall that cracks not the bearing housing itself where the aluminium is thicker.

Heavy handed fitting of bearings and/or crankshaft is usually the cause, rather than an intrinsic weakness of the crankcase casting.

The thin 'end wall' of the crankcase basically functions as an oil baffle, the center hole being roughly that of the mainshaft diameter or in some cases the bearing inner race. Obviously it is also the 'seat' for the outer face of the main bearing serving to locate it correctly within the case. However,the main bearing should be held in position by the 'fit' of its outer race in the crankcase and there is no direct load on the end wall.

So, as long as the piece is not about to drop out it shouldn't cause you any trouble..I have seen a number of engines that are running quite happily with these hairline cracks.

The main thing is not to exacerbate the problem when fitting new bearings or the crankshaft assembly.

First check the fit of the bearings on the mainshaft..a snug 'hand tight' fit is ideal and the shafts can be carefully reduced with some emery cloth strip to achieve this degree of fit..They may already be like that, or even a little looser..this is quite normal as long as there is not excessive play. When fitting the bearings check there are no burrs or damage in the bearing housings. Next heat the cases evenly to about 100 degrees..you can do this in the oven or with a propane blowlamp or similar.

Put the bearings in a platic bag and leave them in the freezer overnight the night before you do the job. This will ensure the maximum size difference between the bearing and case before fitting. You will then find they should just drop in if you take care to get them square to the housing.

Note my comments regarding the fit of the bearings to the mainshafts would be OK for the BSA engine..check that is the case with the Norton before proceeding. The key thing..and the point of it all, is not to exert any more loads to the already cracked case if at all possible.

I'm sure one of the 'Norton men' will weigh in with some advice if it differs to what I have written.

I would be inclined to avoid any kind of welded repair unless absolutely unavoidable due to the attendent risks of distortion of the cases, the difficulty of cleaning any penetration from the bearing housings and the problems that can sometimes occur with wartime aluminium cases (and older cases generally)...Ian

email (option): ian@wright52.plus.com

Ian, did our posts cross ?

I quite agree with your comments about having the inner race a push fit on the mainshaft. On the timing side, it is pulled up tight by the oil pump worm nut on the outside of the crank pinion anyway so it can't go anywhere.

The oil baffle aspect is one that made me pause for thought. Old Edgar Franks must have left it there for a reason...on the other hand, knowing Nortons, the reason might simply be 'We've always done it that way' (back to the days of total loss oiling probably !)

However, the fact that about 80% of wartime production seems to have had the larger opening suggests that it is not a problem to remove the damaged material.

On the cases that I have here, the material has definitely been pushed inwards rather than outwards by the bearing...You can even see were the bodger stuck his lever to get the pinion off...and no, it wasn't me !

Really they would only need welding on the surface as opposed to "veeing" out the metal and then a quick disc off to clear the rear of the gear, this is simply to stop the cracks from spreading, but I do agree that it should just be removed, retaining only enough to hold the bearing.

email (option): davmax@ntlworld.com

Thanks,

the fit for the bearing is fine, I removed the bearing by heating up the crankcase otherwise it was not possible to remove the bearing.

According your advise I will remove the area with all the cracks to make sure loose parts will not damage the engine while running. Was not sure about the oil flow but looks like this is not a problem with this kind of engine.

Phillip

email (option): phillip.thaler@gmx.at