My 16H has been 100% reliable this year. I suppose that it was all too good to last.

I'd planned a longish trip to a Norton club meeting in West flanders this weekend. Everything planned to the smallest detail. Bike checked and double checked and loaded up on Friday evening.

The bike started on the second swing and ticked over perfectly. I left it ticking over and sent a quick text message to the chap I was meeting outside Leuven 'Just Leaving'

I pulled out of the road, down into the village and everything was fine. I waved to one of the neighbours outside the bakers...it was one of those perfect days...then suddenly it started to lose power...first thought was that I'd forgotten to turn the fuel on but that was OK. I managed to change down and ride another fifty yards and it died.

There were no obviuous symptoms so I tried to re-start and found a complete lack of compression. This rang alarm bells as I had checked the tappets in the week and found the exhaust side quite loose (about .012" instead of .006") I couldn't imagine what could have gone wrong but pulled the cover off to check. It's difficult to tell with the motor warm but there still seemed to be clearance. I backed the adjuster off a couple of flats but still no compression.

Faced with a push back home, I packed up the tools etc. Prior to pushing, I tried again and it had compression once more so I started it and set off carefully on a circular route that would allow me to turn back if needs be. Sure enough, after about half a mile, it lost power again so I turned off and headed home, losing power all the way.

At one point, I looked downwards and saw that the forward part of my beautiful NOS dull chromed silencer was glowing so I shut down and pushed in.

Head removal showed no immediate signs of damage although it's clearly been running rich as the piston crown has been washed clean apart from some tarry deposits closer to the valves. ex. valve looked to be an OK light biscuit colour.

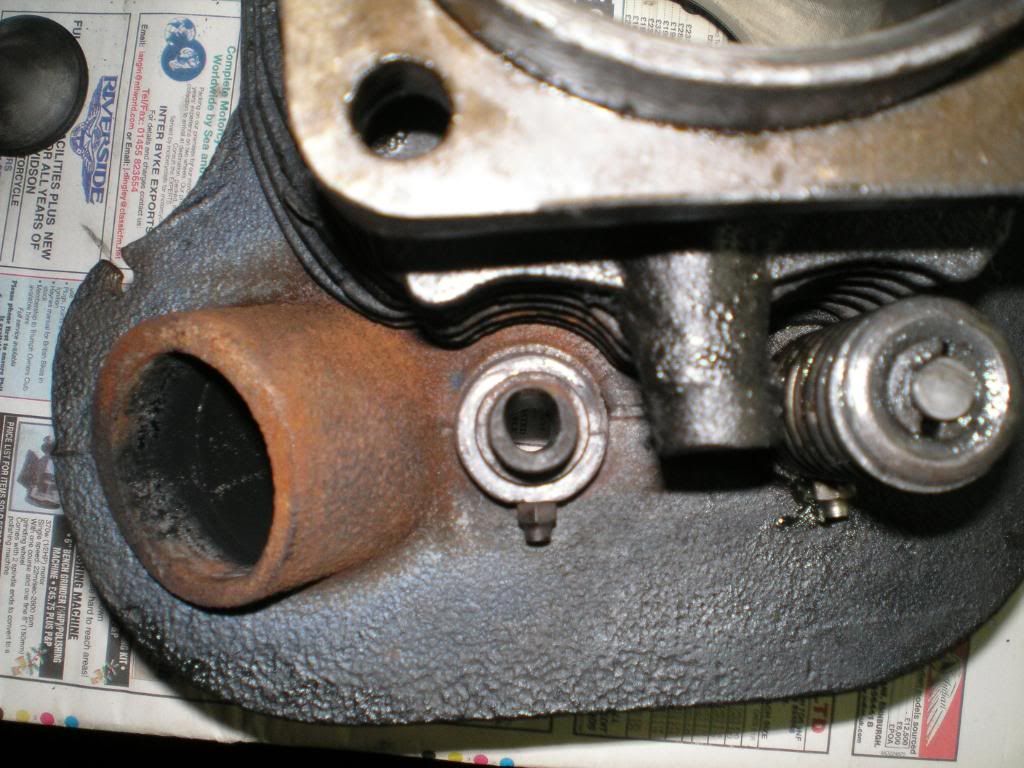

More worryingly, the exhaust valve guide seems to be completely knackered and it's done not much more than 1000 miles. On full lift, there is about 1/16" movement at the valve head and it appears that it is not coming down square on its seat initially and presumably this is causing the compression loss. I wonder if fidling with the tappets has caused the valve to rotate and lose the one place on its sitting where it sealed ?

With an apppointment to keep, I didn't have time to investigate further and tugged the Commando out of the garage for a wet weekend in company with a friend's 16H - the Commando returned better fuel consumption !

Could a badly-seating exhaust valve cause this sort of overheating in the silencer ? The painted down-pipe is showing no signs of heat. I haven't checked ignition timing yet but it had been running well and on its own doesn't explain the loss of compression. A quick visual of the valve operations and overlap doesn't seem to suggest that the cam gears have turned on the shafts.

I put eighty miles on it last Sunday and it had no symptoms at all, although the wear on the guide must have been present. I'm still puzzled by what has caused that. There is no positive lubrication on these early model guides but they've been regularly greased.

The base of the valve stem sits on the tappets in the crankcase. I imagine that if the valve guide was not in line with the tappet then there would be some side thrust on the guide but this level of wear seems extreme. Guides are cast iron and the valve is non-magnetic New Old WD stock.

Has the over-rich mixture washed the lubrication from the guides ?

All suggestions welcome as to symptoms and cause.

At the moment, I'm feeling no great urge to pull it apart. First priority is to get the tent dry and the Commando clean. Fortunately, the Commando gave no problems at all as it made the trip through the pouring rain and hail with only Whitworth spanners and my 16H spares kit.

At least one 16H made the trip...Just a shame that it wasn't mine.

Rik,

sorry to read of your woes, and i am of no great help on mechanical issues, other than to say that it must be related to Ian Wrights recent post which included;

"The wartime Nortons seem to be pretty reliable and robust." Tempting fate indeed.

The glowing silencer is interesting, that's a long way down the exhaust for the combustion to be taking place.

Just was well you have a Commando as back up.

could there be carbon build up in the silencer restricting pressure?

thanks barry

email (option): mrsbfuller@hotmail.co.uk

Hi Rik, Problems with serious failure or recession of the valve seat would cause a decrease in tappet clearance rather than an increase, as the valve sank into the seat. Problems that could cause an increase in tappet clearance woulds be a failure of either the head or foot of the tappet, the cam itself or the end of the valve stem..all pretty unlikely.

So I would imagine this increase in clearance was just down to a movement of the tappet adjuster...

Retarded ignition timing would be a possible cause of overheating, which you obviously have. However, you do not report any loss of performance at the mid to upper end which would be a result of that condition.

Weakness of the fuel mixture is the other common cause of overheating. That could be caused either by a fuel supply problem, contamination in the carb (blocking jets etc.) or an air leak.

As you are experiencing a loss of compression which appears to be related to engine temperature I don't think that fuel supply or related carb contamination are the most likely cause though.

Heat related loss of compression is most likely to be caused by a failure or partial failure of the head gasket or exhaust valve seating. Other possible but less likely causes are piston ring problems or insufficient valve lifter clearance.

Breakdown of the exhaust valve seal can be caused by a deterioration of the valve seat or valve face or the valve face not being true to the valve seat.(a slightly bent valve)

In that case air is drawn up the exhaust pipe and past the valve on the induction stroke resulting in a weakening of the mixture and overheating.

Head gasket failure is self explanatory but they can usually be heard 'squeaking' when on the compression stroke and you haven't mentioned that. Again though, air will be drawn in here on the induction stroke.

I would put my money initially on the exhaust valve seat, face or the bent valve..all of which can be worse when the engine is hot than when it isn't. That would account for the overheating as well.

A possibility ref. the valve guide is that general heat transfer, and particularly heat transfer through the stem of an overheated valve, might have melted the grease causing a breakdown in guide lubrication and as a consequence rapid wear...Ian

email (option): ian@wright52.plus.com

Thanks for your thoughts Ian.

I wasn't worried by the fact that the exhaust tappet clearance had been loose and only mentioned it in case my fiddling could have been contributory in some way. I've adjusted tappets hundereds of times on various engines so I don't suspect that I slipped up, but it's possible. That said, I had ridden such a short distance that I don't think it could have caused major damage.

I checked the tappets after initial re-tightening but had left them alone since so it was probably just settling in.

The bike was fine last weekend, it had its first trip on the motorway when I got lost coming out of Liege and then had a thrash at an indicated 60 mph, just to see how comfortable it was. I parked it up with no symptoms whatsoever.

The head gasket is discoloured but I can't see any evidence of blowing and hadn't heard the wheezing.

The engine has been a bit 'blatty' on the overrun but I put that down to carburation / fuel. It was certainly like that in Normandy and it didn't seem excessive when compared with those around me.

If a Norton has worn guides then it will certainly run weak as it will draw air in rather than oil as the guides are open at the lower end.

The valve seat doesn't look damaged, so far as I can see with the valve in situ. A bent valve occurred to me but how the hell does one bend a valve in a side-valver ? I know how to tangle 'em in ohv engines. There are no witness marks to suggest that the valve has floated up to the head.

The fact that the valve doesn't seem to be coming cleanly onto the seat might well suggests a bend.

I'm still wondering if having turned the valve during adjustment, I might have altered an alignment which had been allowing a seal.

As with all these things, it's a case of trying to work out what caused what.

Could a sticking valve cause that sort of overheating so far down the exhaust system ?

At the moment, I can see the need for a valve and guide plus a re-cut and I'm tring to rule out any other aspects in order to avoid the same thing happening again.

I would refit the valve to the barrel exactly as is (with the barrel off the bike) and then pour some thinners down the exhaust port...any leakage past the valve will indicate a seating problem....Ian

email (option): ian@wright52.plus.com

Cheers Ian,

The valve is still in place. I haven't touched it today, just scowled at it.

Could it be incompatable valve/guide materials accelerating wear?

email (option): davmax@ntlworld.com

It could Dave although all the parts were ex-WD NOS. There is no shortage of those.

As far as I'm aware, the guides never changed but the exhaust valves were altered to austenitic steel later on.

These valves are non-magnetic. I assume that they have hard chromed stems. There were certainly no 16H bronze guides.

I've not measured the wear yet but the rocking that I can see at the moment is much more extreme than anything I've come across at this sort of mileage and there are plenty of people who ride 16Hs further and harder than me.

Could ethanol fuel be part of the problem ?

Incompatability of materials shouldn't be an issue..Austenitic valves will run in cast iron guides without the addition of hard chrome plating and this was not done..at least not on the considerably more exotic M20.

I would discount the effects of Ethanol fuel...I am happy enough with the observations of people such as Joe Rosson who lives in the States, that he has not experienced any noticeable problems with his M20 and other old machinery...despite a 15% Ethanol content in the fuel.Ron Pier experienced very similar problems with his M20 a year or two back and it turned out to be a valve related problem....Ian

email (option): ian@wright52.plus.com

Rik, I had a bent valve after overheating on a motorway ride of 30 miles in france on the B4, and that was an N.O.S. one, and that B4 had only done about 600 miles, never got to the bottom of that, but it kept on running, oil coming out everywhere!! and started first kick!

The tappets on most bikes are offset, to make them rotate, so don't worry about that.

Hope this helps somewhat.

Lex

email (option): welbike@welbike.net

That's interesting Lex, perhaps I just got it too hot and of course on the '37 pattern engine, it won't be sucking up oil but air, making it run hotter still.

The valves certainly seem to be offset but I'm not sure if mine had been rotating as they should.

That shouldn't be too much of an issue...M20 valves don't rotate appear at all...at least Ive never caught them doing it. As a matter for discussion how does a flat tappet head and a flat valve stem, lifting in a vertical plane and offset or not, impart a rotating action on the valve?..Particularly when one end of the valve is pretty firmly held by the the collets, valve cap and spring and the other end of the spring is sitting on the barrel casting...Ian

email (option): ian@wright52.plus.com

Take that muffler off, and have a close look at it's guts!There's something odd about that blueng way down there. A blocked muffler?

Hi Ian,

I think what Alex meant is that the tappets are rotating, not the valve,

Which clearly cannot rotate:

When the cam is hitting and pushing the tappet, it hits it almost on the outer margins,

Off-center, causing it to rotate.

When I took out the tappets from an old engine I rebuilt and looked at the bottom side of the tappet,

I could see the circle created by the tappet rotation on the face of the bottom side, (where touching the cam).

Hope I understood you and Alex correctly..

Noam.

email (option): noam10@gmail.com

Yes I think what Noam said is correct.

Lex it did die eventually! We had to come and tow you in at Etreham.......In the rain....But the young ATS girl kept my spirit up. Ron

Ron

email (option): ronpier@talk21.com

Yes, the tappets, but was actually thinking of Matchlesses, they don't have cam followers as such, (as on Nortons) and the tappets are deliberatly offset to make them rotate, so not to wear in one spot, and make them live a lot longer.

Ron, that was the "other" Big 4 (mine actually) and it had a sticky exhaust valve, after cleaning it was OK, also everything N.O.S.

Yes the young ATS girl certainly holds things up

She'll be riding your C10 next year!!

Cheers,

Lex

email (option): welbike@welbike.net

Ah right, so she is now Tibo's girl? You do share your women around

Ron

Ron

email (option): ronpier@talk21.com

Ron

RonHahaha, you are so wrong here, she's his sister!!

But you're just teasing I know,

Lex

email (option): welbike@welbike.net

Thanks for the anecdotes, chaps. At least I now understand that valve troubles on Nortons are not exactly unheard of.

I've now got a pretty good idea of what was causing the symptoms on mine. Not to put too fine a point on it, the newness has seriously worn off the valve guide. In fact it's a wonder that it ran at all and I think that in adjusting the tappets last week, I must have turned the valve from the one sweet spot where it was able to sit more or less where it should have.

What I now have to do is work out why !

I've never seen one as bad as this and the motor has only done just over 1000 miles.

The fact that the wear (it measures .432" instead of .332" per a new one) is sideways seems to indicate some side thrust on the valve operation and at present, I can't see a cause of this. The follower and its guide in the crankcase have just perceptible play and seem to be in line. There is just a nice circular polished withness mark on the follower cap and the valve stem has no wear and certainly no evidence of line contact on the edge.

What I have found is at least three different variations of valve and the one used here has the collet groove closer to the end so it may be that valve spring pressure was not sufficient to pull it down onto the seat.

I've always been careful to keep the valve cover away from the springs (most of these covers show signs of having rubbed)

Is this sort of lateral wear the usual pattern ?

The valve 'seems' straight and the seat appears centred on the guide - If I push the valve up into the seat, the stem comes to sit centrally but pressure on the edge causes it to rock in the seat .

I wonder if the bore for the guide is not at 90° to the cylinder flange ? Should I cut my losses and try another barrel ? It seems a shame as the new Wellworthy is looking great with just a dull greyness on the thrust faces.

Blimey Rik! that looks like it's just about to burst through the side. At least you have found the problem. Now for the cure?

I think I would remove the old guide, then work out some sort of accurate 90' T shaped gauge to put through the guide bore to eliminate the bore having been drilled off square.

If that proves OK. I would then simply fit a new guide and valve and re-cut the seat. Then sit the barrel in place and look carefully at the follower to valve contact and action.

Have you had a hardened valve seat insert installed? The problem I had with my M20, was that the seat was not pressed in with enough interference fit and was able to move. Eventually it tipped and bent my valve.

Ron

email (option): ronpier@talk21.com

It is quite bad, isn't it ?

It is quite bad, isn't it ?

I had a good look at the alignment before I took it apart (and afterwards) and I can't see any problems. I would have thought that any side thrust would have to be pretty extreme to cause this sort of wear. There are no inset valve seats.

I'm used to the considerable scuffing action on the valves in Norton ohv twins and although it does cause wear, it's not in this league.

A contact over here says that he's seen similar with pattern guides made out of standard rather than pearlitic cast iron. I can imagine that non oiled guides with no graphite in the iron is a problem.

Unfortunately, I can't remember where my valves and guides came from during that whirlwind six-year spending spree so there is no guarantee that they were genuine.

I can at least get proper ex-WD parts from a chap close to here so with a bit of luck, the seat will clean up and I'll be on my way again without too much delay and expense. It's a bit of a bugger though as we've got a club run this Sunday so it looks like I'll be slipping the Commando's clutch again trying not to hit side-valves up the chuff !

Give over you big girl! Two evenings after tea should see that job through, no problem

Ron

email (option): ronpier@talk21.com

Was I right then!!!!???

email (option): davmax@ntlworld.com

Ron

You Tart ! I shall hit you with a cast-iron filled handbag at Netley !

Trouble is Ron, I have to work and I can't get over to pick the parts up till Sunday.

In the absence of any alternative explanation, at least your theory will let me get on and put it back together without expecting it to do the same thing again !

Not seen anything like that on any of my barrels, and I have done a fair bit of miles on my 16H since I got it on the road in 1979.

As you say, Rik, there is not really anything in the valve train that would make the rotary movement of the cam, through the vertical moving cam follower (hinged between cranckcase and timing cover) into a simple up and down movement of the tappet. The bronze tappet guide fitted in the top of the off-side cranck case half is okay, I assume? Then it either is a freak Monday morning grey cast Iron valve guide casting fault, or some sort of distorted valve thing, or a combination of all that. Or a freak valve spring pulling sideways?

I would replace the valve guide, and to be sure replace the valve and the valve spring too, and happy milage to you!

But if has anything to do with the valve spring, you may want to fit that one to the inlet valve, and with the re-occurance of wear in the valve guide (this time the inlet one), at least you can put your hart to rest as you have pinpointed the cause?

email (option): rvanmeel@wanadoo.nl

I don't believe it. It's done it again...the inlet valve is the worst this time. I've put about 500 miles on it since the last top-end job.

I was away on the 16H this weekend. It was fine on Saturday although I did notice that it was popping a bit when I re-started it from cold but it cleared as the engine warmed.

The ride home on Sunday started with the same symptoms which once again cleared but after about ten miles, it began fluffing on acceleration - constant throttle was OK. It felt a little down on power. Over the next twenty miles, it got worse and worse. It was clearly giving symptoms of leanness.

Playing with the timing gave no unusual signs so should have been OK

The usual checks on getting back - fuel flow, stripped the carb - cleaner than it's ever been.

...and then wiggled the valve stems - Exhaust was a bit loose and has some black deposits on the stem but inlet guide has worn to .406" at the lower end (as far as I can tell with the cylinder still on). This is giving me .063" clearance on the .343 valve stem.

The wear has been so bad that there was grey metallic dust on the valve spring.

My photos haven't come out too well. The wear is even this time.

I do seem to have some signs of over-fuelling at low throttle openings. I've chased around with replacement parts, lowering needles and different slides and not really been able to make it run less rich while not affecting drivability.

I'm back to wondering if this ethanol fuel (and I'm sure that Belgium is taking the piss out of the 10% maximum) is stripping any lubrication out.

What's the answer ? 2-stroke pre mix in the fuel ?

I really can't work out why only I'm having this problem. These were ex-WD valves and guides from a quantitiy that the supplier has sold to various owners over the last twenty years, without problem. The bikes are suppposed to be unbreakable. I can't believe that I'm the worst fitter with the crapiest parts and the worst fuel in the history of WD Nortons.

I'm really 'down' with this because I just don't know what to do with it. A museum exhibit is no good to me at all. If I can't ride it then it might as well go in the canal...

Hi Rik..Sorry to hear about the recurrence of your problems. Recent discussions about valve guide clearances seemed to indicate a degree of confusion about what the correct clearance for the Norton should be...Could it be that your initial clearance was too tight causing scuffing on the valve stem which then abraded the surface of the guide?

What did you set the clearance to initially?

M20 clearances are .003"-.005"..and the M20 has positive lubrication via pressurised oil mist from the crankcase.

Another possibility is that the grease you are using is not of the right type and failing to lubricate properly under those particular conditions.

Personally I wouldn't have thought 'petrol dilution' of the lubricant would be an issue...unless you had it set ridiculously rich I don't think it would have any effect...further, the last time it failed it was the exhaust guide and there isn't any 'raw' petrol there.

These days there are some vastly superior specialised greases which would certainly help...perhaps you should consult an oil/grease manufacturer directly with a view to upgrading the lubrication..

I do think though you need to tie down the question of clearance at fitting...Ian

email (option): ian@wright52.plus.com

Would purpose made bronze guides help? Ron

email (option): ronpier@talk21.com

There is no reference in any of the step-by-step WD or pre-war manuals to required clearances or to reaming the guides after fitting. I had perhaps naïvely assumed that they were pre-sized. They're quite thick-walled things.

I don't have the facility to measure them accurately and worked on the basis that if the valve could drop easily through the guide under its own weight then they should be in order.

Last time, I used a molybdenum grease but worried that some of those can form hard particles under load so this time, I did it per the old book and used standard HT grease. The greasing interval back in the day was 500 miles and many owners don't even bother to grease them. They're all having less problem than me.

I have tried to research lubricants but unfortunately, thse days, its about marketing and not customer service.

What sort of clearance would you guess at for a grease lubricated valve ?

Hi Rik..Your method of deducing clearance is not valid...the valve would 'drop' into the valve guide with .001" clearance exactly as it would with .003" clearance, yet whereas .003" might be sufficient .001" definitely wouldn't be..

First you need to decide on a clearance, say .004"-,005" for example. Then find someone with a lathe who can turn up an accurate 'plug gauge' for you. If your valve stem was .350" diameter, for example, and the required clearance was .004"-.005" get them to turn a piece of bar to .354" at one end and .3555-.356" at the other. This would be a 'go, no go gauge'

When sizing the guide you can use an adjustable reamer (if you can get one that small)or a honing tool to bring the guide up to size gradually. When the 'go' end of the gauge just fits and the 'no go' end doesn't you know you have applied the correct tolerance without measuring the actual hole.

I bought a special hone for this job.

Guides usually, if not always need to be sized after fitting....

If I was to guess a clearance for a grease lubricated guide I would say .004"-.005" thou...but I don't like guessing so I will see if I can turn up some hard information. I also have some information on greases somewhere...I'll try to find it all for you...Ian

email (option): ian@wright52.plus.com

Do you have any spare barrels with the valves and guides in, even if they are a little bit worn? I'd take them out of the used barrel if you have any and see how they wear, if they've lived to be reasonable second hand ones the materials are certainly compatable and if they last when you fit them this time you can certainly say that it was incompatability of the materials. If they wear out yet again, I'd say you have a problem elsewhere. I notice that the rocker arm above the cam has a different part number on the 16H to the big 4, so possibly you have the wrong one fitted that is too long or short (I'm not that au fait with Nortons) Or possibly the bushings or casing that they pivot in are worn or misaligned, making the rocker act at an angle pushing over the valve stem.

email (option): davmax@ntlworld.com

How strange is that

Hope you get it sorted Rik

Job

email (option): Jonnyob1@googlemail.com

Oh nooooo  I'm really sorry to hear that, it's terrible news. I have been watching the results of this for obvious reasons.

I'm really sorry to hear that, it's terrible news. I have been watching the results of this for obvious reasons.

If you did have only 1 thou clearance (for example), and the engine had done 400 miles, I would have thought it would wear until it reached a clearance it was happy with (if it didn't nip up first). As the guides are wearing bigger, it can't be a valve to guide clearance problem.

It would seem like a lubrication problem. The plasma nitrated stainless vales from Russell's seem very good. I obviously haven't road tested them yet, but my engineer mate was very impressed with them. You can feel the difference between them and the original valves when sliding them in the guide. Very smooth and frictionless. If it is a lubrication problem, or incompatible metals problem, they might just be the answer.

email (option): horror@blueyonder.co.uk

I'm all for upgrades when available, I run an upgraded exhaust valve in my M20...but you have to bear in mind that the original components did millions of successful miles fitted to these bikes.

With that in mind and the fact Rik has used those (proven) original components logic dictates materials incompatibility can be discounted.

I think clearance at fitting and lubrication are the issues here.

No one so far has come up with an actual, proven, stem to guide clearance figure yet and that question needs to be resolved.

Regarding lubrication I have emailed Morris Lubricants technical department for thier opinions..I have found them very helpful in the past so it will be interesting to see what they come up with...Ian

email (option): ian@wright52.plus.com

Yes, we do seem to be lacking this info

But one question Ian, if the clearance was too tight, the valves would seize up and the bike wouldn't have done 400 miles before a problem arose. The problem has only emerged because the clearance has become too great (65 thou), allowing air to be sucked in the inlet guide, making the mixture weak. Before that the bike ran fine.

Ah unless the clearance started of too big, then the valve would be forced more against the side of the guide, exaggerating wear.

email (option): horror@blueyonder.co.uk

My 1932/33 Norton model 18 was fairly clapped out, but stil noisy like hell and bloody fast. A friend of mine wanted her for a while and whilst preparing that machine decidede to replace valve guides on this open valve OHV, sort out the worn out bearing tolerance in the left hand crankcase and probably did a lot more (funnily the gearbox sprocket was still okay, if I remember correctly

). The new exhaust valve guide wore itself out in two days, on the 2011 Luik-Nancy-Luik run. The material had worn more in that 600 km run than the previuous ones over 20 years and quite a lot more miles. He now has gotten a better grey cast iron material for the guides and trials show hope for a more wear resistent material. Maybe that could be the problem: an unfit material for non lubricated valve guides?

). The new exhaust valve guide wore itself out in two days, on the 2011 Luik-Nancy-Luik run. The material had worn more in that 600 km run than the previuous ones over 20 years and quite a lot more miles. He now has gotten a better grey cast iron material for the guides and trials show hope for a more wear resistent material. Maybe that could be the problem: an unfit material for non lubricated valve guides?

I'll forward his emailadress to Rik, and maybe the two can look into this. Olav lives in Antwerp these days, but does visit the Maastricht region ever so often.

Rob

As I said..I would be quicker to accept that line of thinking if Rik had used aftermarket pattern valves or guides. However he didn't, he used NOS Norton parts. Also there are 16Hs running about now that have had the same parts fitted..Russell Motors must have sold hundreds of them.

Effectively guessing the clearance when fitting new guides must increase the chances of periodic failures..A possible scenario is that the valve stem has 'scuffed' but not siezed due to restricted clearance and then the scuffed surface has ground the guide away...as long as the scuffing is there, the grinding continues.

An examination of the valve stem might serve to confirm or discount this as a possibility...

The suitability of the grease used is also a factor that could bear some clarification..The temperature resistance of a modern High Melting Point grease might not be the only thing to be considered when selecting suitable lubricants..there is far more to grease than that.

Come on you Norton boys..get a grip...get on the Internet to Castrol et al and get a cross section of advice on what is required...and maybe get onto Dr. Norton or whatever he is called and get some information from someone with a working knowledge on stem clearances!...Ian

email (option): ian@wright52.plus.com

I have just had a reply from the boffins at Morris Lubricants. They have quoted three possibilities but are asking for more information...specifically, what was the make and grade of the grease originally specified by Norton?..Let me know and I'll mail them the information....Ian

email (option): ian@wright52.plus.com

The WD Rider's Handbook quotes "Grease GS" every 500 miles - this is the same grease as specified for everything from speedo drive to fork spindles. This was superseded by C600. One diagram that I have shows M220 for the guides.

The BMS book which seems to be compiled from factory sources states "High Melting point grease or grease containing collodial (sic) graphite should be used".

The civilian books refer to 'using the grease gun every 800 - 1000 miles' and in other contexts to 'a suitable light grease' - it's all horribly vague.

Thanks Rik...I've mailed them the info. you have...I should get a reply tomorrow. I'll take a look online at the three 'possibilities' they recommended this evening and see what the specs. of those are...Ian

email (option): ian@wright52.plus.com

I'm not an expert on these bikes, but if you don't mind me weighing in: It seems to me that the guide is misaligned... could there be a possibility that a feature on the cylinder is not perpendicular and that feature (either the top or underside of the barrel or spigot) is being used to align the valve guide during installation? That would account for two guides failing. Just a thought, and if it's completely daft, please remember that ignorance is a temporary condition.

I spoke to Dr Norton, George Cohen, about it tonight. It was difficult, as my measurements seem to be different to Rik's. My NOS valve guides from Russell's are .344" and my original valves are .340"-.3405" so that's 3 1/5 to 4 thou clearance, which sounds the right amount of clearance to everyone. He couldn't tell me any figures either. Like he said, nobody wrote this stuff down and everyone makes estimates on there experience.

I said, the book says to grease every 500 miles, he said well grease it every 100 miles. I mentioned incompatible metals, but he didn't think that would be the case with NOS parts. I said about the stainless valves, and he said there ya go, put in the stainless valves and grease more often..! Simple

email (option): horror@blueyonder.co.uk

So did he give you an estimate based on HIS experience?

....Ian

....Ian

email (option): ian@wright52.plus.com

Hi Ian, he said you could have 2 thou on the inlet and 4 on the exhaust as the exhaust gets hotter. I told him the valve and guide measurements I've got, and he said that'll be it then. He has a couple of 20's bikes that are similar to a 16H with external vales, and he just sprays oil everywhere with them. He doesn't run a 16H, OHC are his thing.

There was one more person who might be able to help, and that's Len Patterson of The cylinder head shop.

email (option): horror@blueyonder.co.uk

Hi Horror...004" for the exhaust would be about the figure I would use if making an educated guess...though probably I would go another thou..and I would go .003"-.004" for the inlet personally, based purely on M20 experience.

I have also now e mailed the Castrol technical department for a recommendation on a suitable grease..so hopefully tomorrow I will hear from them amd Morris's who I emailed back with some additional information earlier this evening.

Len Patterson should be able to give you some info...if he can resist trying to sell you phospher bronze guides!

...How about the Norton Owners Club or the VMCC?..I know the latter has 'marque specialists' for most models...Ian

...How about the Norton Owners Club or the VMCC?..I know the latter has 'marque specialists' for most models...Ian

email (option): ian@wright52.plus.com

Hi Rik Try George,he is the VMCC Norton single man

email geo@norton.uk.com

Hi Pat, I think you are referring to George Cohen, who I spoke to earlier.

email (option): horror@blueyonder.co.uk

Rik, I have 2 16H valve guides, I have no use for, you're welcome to them.

Have no idea about the quality?? there's a blue sticker on them I think, will have a look.

Cheers,

Lex

email (option): Welbike@welbike.net

Kevin, all thoughts are welcome ! I don't think that the problem is misalignment. On this 16H, the valve stems are lifted by quite large hexagon adjusters and I can't see any odd wear. There isn't any actual positive location to align badly, if that makes sense ?

I have tried to contact George Cohen a few times over the years and never received a reply. I use to know Len Paterson quite well when he was in Wimbledon. I wonder what sort of guides he fits to grease-lubricated valves ?

Lex, I'll mail you. I have one spare set at the moment (from Alain Touchet - that's mostly ex-Garreau stock but could be from anywhere by now). I'm a bit reluctant to just slap it back together until I can come up with some sort of cause and theoretical cure..

Dave, I don't think that the 1938 pattern (which is what the WD Big 4 had) flat lever followers will fit in my engine. The lever followers lift tappet rods which run in bronze guides screwed from above into the crankcases. these are new and appear OK. The valve stem sits on the adjusters on top of these rods with nothing restricting that it finds its own location (within reason) so there shouldn't be any significant side-loading.

I like your idea of trying used parts although what I have are all too far gone, I fear.

Hi Rik, I phone George Cohen rather than e-mailing him.

The other person I tried was Mike Pemberton, who is the NOC SV & OHV expert. This is his reply.

Hi Dave,

This is the second time that I have heard of this happening. In all honesty I don't know the cause!

Again if I am honest I have only rebuilt three 16H engines in the last 20 years.

The clearance should be about 0.004" but I don't know what grease was recommended.

The last person that I spoke with over this problem thought that the guides that he bought as New Old Stock were in fact pattern items made from inferior material.

I suggested making a pair from Bronze and he thought it was a good idea but he never got back to me so I don't know if it worked or not!

I am really sorry that I can't be more helpful.

regards,

Mike.

I notice he says the 2nd time...! Was the 1st you as well Rik?

So the only thing to do now is measure the clearance when you get new parts and see what happens.

email (option): horror@blueyonder.co.uk

After reading all the posts, can any of you tell me why both damaged guides appear to have worn just on one side? After thinking about it more, why have they done this instead of just wearing all round the guide? There must be something wrong with the alignment, the main thing is that it appears variable, in that whatever has happened can happen to either guide, possibly resulting from something when you replaced the barrel on for the second time which then caused the inlet valve to wear instead of the exhaust Maybe it's time to start measuring if the valves are running parallel to the bore, or if the head gasket face is parallel to the base gasket and if both of the little push rods are at exactly 90 degrees to the base gasket face preferably under a load, so that you can see if they "run out" then, they may appear ok under no load, but when a load is applied they may "run out" then. I know it sounds unlikely, but there may be a machining error. The rocker arm will probably lift the push rod "true" when there is no load but when one is applied it may run out a little, or maybe the timing cover is a bad match for the crankcase, in that it's bushes are misaligned on the pivot, causing it to tilt to one side under load, I know the little pushrod has it's own guide to keep it vertical, but surely some of an uneven lift would be transferred to it. Does the timimg cover have any locating dowels to accurately locate it on the crankcase? If not, it could be this, or if it does, are they in line, I know it's not something you would normally check, but after a problem like this I'd start investigating.

email (option): davmax@ntlworld.com

I have contacted Morris Lubricants, Castrol and Conoco Philips regarding grease specs..When all the answers are in I'll post the relevant details.

It is possible I will be carrying out the repair work for Rik..if that is the case I will apply a stem clearance of .004" to the inlet guide after fitting and .005" to the exhaust. Rik has examined his engine for any obvious misalignment of components and so far hasn't come up with anything..but I agree..a thorough look at everything is required to ensure another factor is not being missed...Ian

email (option): ian@wright52.plus.com

Rik, only found one guide, has a blue sticker on it from Bantam John, so have no idea about the quality, but seems nicely made, and old.

Re. putting bronze guides in, I would never do this, the expansion coefficients are totally different, and they will loosen up, as a sidevalve runs slightly hotter.

Cheers,

Lex

email (option): Welbike@welbike.net

I am stunned that even the Norton owners club SV single expert couldn't say what grease to use! There must be 100's of WD16H's still being ridden. Can't anyone say what grease they use and how often they apply it?

email (option): horror@blueyonder.co.uk

Hi Horror, I share your disbelief..It's totally beyond me that no one knows the guide clearances and grease specs. for such a common bike.

When a self proclaimed Norton single 'specialist' like George Cohen and the Owners Club singles 'expert' can't come up with a concise answer to such a simple question it makes you wonder how they got the reputations and positions they have.

Mind you, I've always said for every hundred experts there's one expert..

...Ian

...Ian

email (option): ian@wright52.plus.com

Thanks for your thoughts on this.

Dave, the wear looks even this time. My crappy photo with too much shadow is causing it to look odd. The wear looks 'normal' just more like 50,000 miles than 500. I've looked and looked at the valves as I turn the engine and everything appears to lift square.

Horror, it was indeed me who spoke to Mike Pemberton last time. In his defence, he works mainly on the ohv engines. I don't think that sv owners generally follow the paid-for help route. He's a clever engineer who builds some very quick short stroke ohv engines but these are mostly based on the post-1948 engines which are quite a different beast and share only the model name and almost no components.

As I mentioned on the earlier thread, Edgar Franks mentions in his text, a clearance of 0.002" to 0.003" for both ohv and sv engines of the early grease lubricated valves 'when new'

...and the WD manuals list standard grease for lubrication. It doesn't ever seem to have been a problem.

I really think that no-one knows as no-one has done anything except bang in standard guides and run with ordinary grease.

There was quite a scare over valve stem lubrication when lead was deleted from fuel but with the suggestion that valves and guides which had run with lead were pretty well lubricated for life.

Is anyone using an upper cylinder lubricant / lead replacement ? Should I be running a bit of 2-stroke premix for the valves ?

Are the valves from Russells made by GS Valves ? It might be worth me asking them what they think about suitable guide material if I use coated valve stems.

I run a 2 piece exhaust valve in the M20 with a Nimonic 80 head and stainless hard chrome plated stem. No problems with that after extended mileages...in fact I can't remember tha last time I looked at it.

Conoco came back to me with a grease recommendation so vague that I wouldn't put much faith in it..basically, 'try one of our molybdenum greases and see how it goes'.

Morris Lubricants sent me a couple of e mails and recommended a first and second choice...first choice 'K65ms' has a very high operating limit temperature wise and is a 'Bentone' grease. Second choice was 'K48' which is a Lithium grease with molybdenum disulphide. Interestingly they commented that 'over greasing' should be avoided..but quite what that means in practical terms is not so easy to pin down. Full specs forK48 can be downloaded from the Morris website as a PDF. Specs for K65 have to come directly from Morris's as they don't sell this one on line.

I'm still waiting for a reply from Castrol.

All three companies no longer make high temperature colloidal graphite grease but it can be found on the internet so I think some further searching is required.

No doubt none of the major oil companies make a grease specifically for this outdated application..Regarding clearances, 'No one knows because they just bang in standard guides' doesn't seem likely..M20 guides nearly always need sizing after fitting to achieve the specified clearance. Are there really NO Norton publications that give this information?..Was it a state secret?...I'm still struggling with the concept that the 16H with it's 'intermittent' lubrication was designed (according to some) to run with a smaller stem clearance than the minimum M20 clearance....Ian

email (option): ian@wright52.plus.com

Thanks for all your research on this Ian.

K65s sems to be listed by Morrises under the industrials section but in 12.5 kg tins ! I dread to think what it costs !

http://www.morrislubricants.co.uk/scripts/prodView.asp?idproduct=362

I'm puzzled by the lack of info, Ian. The books are full of piston and ring measurements, bush sizings, end floats etc. but nothing about the valve guides. In answer to your questions though - why would the Norton have smaller clearances ? - There was no oil to get up there so why leave a gap  ? and maybe they were more susceptible to drawing air in once the clearance increased ? That's what gave me trouble this time.

? and maybe they were more susceptible to drawing air in once the clearance increased ? That's what gave me trouble this time.

Hi Rik, Yes I think the stainless valves I bought from Russell's are G&S Valves.

It looks like you are the only person who's had this problem, and whatever you did the first time, you replicated it exactly the second time.

I have been puzzling over it and all I can come up with is lubrication. If the valves were too tight it would have seized up and they would be badly scored. I'm guessing it didn't and they're not scored, so the valve to guide clearance wasn't the problem until it became too large the engine was suffering. If the cam followers were out of line, that would stand out, as the valve and adjuster would be out of line, and you say there's no wear on the follower guides. That only leaves lubrication.

What grease have use used? And if the bike did 500 miles, does that mean you only greased them once? (as per the WD service book)?

I was talking with a mate this evening about this problem, and he pointed out that his Norton Dommie has cast iron/ steel (whatever they are) guides with an oil seal on top. So no oil can get to lubricate them, and all modern engines are like this. So why don't they wear?

email (option): horror@blueyonder.co.uk

As another self proclaimed expert ( I did do app. 80.000 km on my WD-16h ober the last 32 years) I must admit that lubrication, or lack there off IMHO is not the cause. I have neglected that part of daily maintenance quite often. After the first engine rebuild somewhere in 1993 I did use Castrol R as a petrol additive for a number of years. But people would sniff and tell me I wasn't on the Norton so I stopped using that.

so I stopped using that.

As the two guides seem to have come from different badges of parts, we can assume that material failure is not the issue. Than we have to look how mechanically the thing is set-up. I would go for finding a cure, rather than finding the cause.

If for one freak reason or another this engine is jinxed, just get on with it and replace it. First start with the barrel and parts involved, that would rule out faulty material for the guides themselves, n'est pas?, and if with 'proper run-in' guides the problem re-occurs, it has to do with the bottom bit giving off bad vibes.

Just my two P worth.

Rob

Rik I'm sure it was Rob VdB that told me, in that laid back fashion that he has. That he never bothers to grease his guides or put oil in the chain case.

Other guys refer to you having had a repeat occurrence. But it's the inlet this time?? If you had a misalignment somewhere that wore that first exhaust guide, it would surely have worn it again.

I'm not helping Rik! Just thinking out loud! Ron

email (option): ronpier@talk21.com

I'm not clear how you would identify a cure without knowing a cause. If ,for example, the cause was incorrect clearances you would be likely to duplicate that, even if you fitted another barrel, if you failed to identify that fault.

Drawing air up the valve guide I don't feel would be an issue with a broadly 'normal' clearance. In the case of the M20 which has a 'sealed' tappet chest oil is supplied to the valve guides by oil mist forced through a hole in the top of the crankcase by the downward movement of the piston, which pressurises the cases..

So, unlike the Norton, as well as suction in the inlet port their is also pressure at the other end of the guide. However, only when guides are badly worn does the passing of air via this route into the cylinder become an issue.

Rob van den Brink notes on his website that he ceased to grease his valve guides at all, yet reports that his bike is still running ok some time later. Rob van Meels comment that he is not overly careful regarding lubrication intervals as well tends to indicate that the focus on lubrication is a 'red herring' and it is not critical.

Interestingly, over greasing of bearings can be a problem as too high a level of grease in a bearing leads to increased friction...

It seems to me that if the guides are to be greased then the temperature range of the grease is perhaps the most important factor..when greases are heated beyond their limits the liquids evaporate away and leave solid residues which could effectively reduce clearances I would have thought.

Looking at the question of the clearances applied it is clear that at this point there is a total lack of concise information regarding the correct figure to apply at fitting, either from any Norton owner, any of the 'experts' or any Norton publications.

I haven't yet come across any information on the Triumph side valve engines though I am looking for that in amongst all my info.

Both the Triumph and the M20 have positive guide lubrication but do share the general layout of the Norton and are both subject to the higher operating temperatures of sidevalves. As such they represent the nearest thing to a comparative figure for guide clearances.

As no one seems to actually know what the guide clearances were when thier engines were put together there is no evidence to suggest one way or the other that the smaller clearances mentioned are, in fact, workable or not.

As Rik did not measure before ,or resize and measure his guides after, fitting and as in the case of the M20 this is nearly always required to achieve the .003"-.005" clearance recommended, it seems likely that the bike has already run with 'low' clearances.

If this is a factor, then the results would infer that it is not a good move.

Off the back of two guide failures and with a lack of good information to the contrary it would seem to me to be an entirely logical experiment to apply the clearance figures of the M20, which are known to work. At the very least this would answer the question of whether the clearances are a factor and would allow results to be assessed around a known 'baseline' figure rather than randomly applied tolerances..

Beyond lubrication and clearance and with no evidence to indicate there is some 'structural fault' with Riks particular engine (though accurate checking of the alignment of the guide bores might be worthwhile) I can't currently suggest any other reasons for the failures..One final amazing fact..I went right through the 'Motorcycle' wartime publication covering the overhaul of military motorcycle engines and despite the noting of numerous clearances during refit at no point, anywhere, for any engine type, are valve guide clearances mentioned..Ian

email (option): ian@wright52.plus.com

Rik/Ian, just had another thought, when dissasembling the first time, did you keep the valve springs with the valves, or did they get mixed up? so you could have fitted the exhaust valve spring to the inlet valve assy.??

This could lead to a faulty valve spring maybe, causing the valve to press more on one side, hence the wear??

Just a thought,

Lex

email (option): Welbike@welbike.net

Had a look through all Pitmans books etc. and nothing at all about clearances!! is there no Norton WD inspection standards guide, as for M20 and G3L bikes??

Found this leaflet, date unknown, and the greasing of the valve guides is not mentioned at all!!!

Ok, did some more searching, we go from none, (above) to 500-800 miles interval (Pitmans book) to Daily! in the Military Police Questionnarire from 1943:

Mind you the MP's must be a greasy lot!! (no offense Ramon )

)

Cheers,

Lex

email (option): Welbike@welbike.net

For what its worth i was reading a 1948 D.W.Munro book on BSA's other day & in it the author mentioned a phenomenon applicable to sidevalve bikes. Where SLIGHTLY retarded ignition that does not in any way affect performance (because of the nature of sidevalves limited power range) can cause such intense heat to cause glowing of the exhaust on a drive of just a mile or so.

Page 71 - 72 (sixth edition 1954)

I have had another e-mail from Mike Pemberton NOC SV expert.

Hi Dave,

yes it was Richard Payne!

You say that you have new stainless valves but are they actually 21-4N Austenitic valves?

Austenitic material is not really compatible with cast iron. We get away with it because of the 0.004" stem clearance in the guide, if they have been plasma nitrated they may be OK. I did tell Rich to try a bronze guide but again he used cast iron and had the same problem. I can't see that these guides are original new old stock. I just feel that they are made from an inferior material. The WD machines clocked up thousands of miles in sandy conditions and never had this problem so what else can it be but the guides?

Ok, to clear up the stainless valve part (in case Rik decides to go that way) I phoned G & S valves today and they confirmed what my engineer said, that the valves are pulse plasma nitrited then super polished. These are fine for cast iron guides.

email (option): horror@blueyonder.co.uk

Now I'm confused about valve steels ..Jessops G2 is (was) a high nickel austenitic steel developed and used by BSA fot the manufacture of exhaust valves. You will see 'G2' stamped into the face of original valves...and as we all know these were routinely run in cast iron guides in various BSA engines. 21-4N is a later developement (60s) and is also an austenitic steel, the '21' referring to the 21% Nickel content.

..Jessops G2 is (was) a high nickel austenitic steel developed and used by BSA fot the manufacture of exhaust valves. You will see 'G2' stamped into the face of original valves...and as we all know these were routinely run in cast iron guides in various BSA engines. 21-4N is a later developement (60s) and is also an austenitic steel, the '21' referring to the 21% Nickel content.

I think I recently sold my last original exhaust valve so am unable to examine one to see if it has any obvious stem treatment such as chrome plating..though I can't say I have ever noticed any.

Does anyone have a NOS valve they can take a good look at?..Ian

email (option): ian@wright52.plus.com

I note Mike Pemberton mentions a .004" stem clearance in his reply..is that for the 16H?..and where did he get the figure from?...Ian

email (option): ian@wright52.plus.com

Hi Ian, this is what it says on the G&S Valves website;

The whole unleaded question regarding valves is a bit tricky to explain. To begin with certain 'older style' engines can run perfectly satisfactorily on plain 214N material, due to the fact that they are not a modern day 'lean' burn, high revving engines, expected to do modern day mileage and service intervals.

Unfortunately every engine is different. What we have found is that if the cylinder heads have had modern day ‘unleaded’ hardened seat inserts fitted the seat insert will most probably be too hard for the valve which could excessively wear the valve seat. In this particular case we would recommend a stellite seated exhaust valve.

For racing use unless the engine is a very heavily loaded engine or has forced induction you could usually get away with 214N or 1.4882 material as the valve will not be in service as long as a standard road going valve.

As a rule of thumb any exhaust valve running on modern day fuels should NOT be magnetic, if so, it is a martensitic (magnetic) steel which nowadays is used as inlet valve material. 214N which is an austenitic (non magnetic) stainless steel developed in the 60’s and designed to run on leaded fuel. Some older style engines pre 60’s used EN54 (non magnetic) steel some with a stellite 6 seat or EN59 / EN52 both of which are magnetic materials. Any of these materials would not be as good as a plain 214N exhaust valve. The addition of stellite seats has been implemented due to the demise of leaded fuel leading to excessive seat wear.

The other thing to note is that 214N (austenitic stainless steel) is not compatible to run in cast iron guides without a surface treatment on the stem e.g.: plasma nitride, chrome or tufftride, where EN52 or inlet (magnetic) material without a treatment is acceptable. Nimonic 80A is also not compatible to run with cast iron guides without a surface treatment on the stem e.g.: plasma nitride or chrome, but is acceptable to use unleaded fuel without a stellite seat.

Hi Ian, I've just seen your next post, yes that's for the 16H. I don't know where Mike got that figure from, I have posted the reply as I received it. Most people have agreed that 4 thou is the acceptable clearance.

email (option): horror@blueyonder.co.uk

I've just checked my e-mail and there's another reply from Mike Pemberton;

Hi Dave,

I don't think that it is down to lubrication! Take any modern engine whether it be diesel or petrol. All valve guides are fitted with stem seals, when you strip a modern engine the guides and stems are bone dry. Even petrol engines are now capable of 150,000 to 200,000 miles!!!!!!!!!!!!!!

I don't think that the guides available are genuine new old stock. Perhaps they were all used up back in the 70's and maybe a large batch of pattern guides were made from incorrect material.

But this is only my theory.

regards,

Mike.

Well that coincidently answers my question about valve guide oil seals. It seems lubrication isn't a problem with valves and guides, but the materials used is crucial.

email (option): horror@blueyonder.co.uk

I see the direction of Mikes reply with regard to materials, but he is making a sweeping unsubstanciated assumption in advancing his 'theory'..Namely,that NOS items ran out in the 70's and that the NOS guides which Rik obtained (twice) were not ,in fact, NOS but pattern items. There is no evidence to support that proposition and NOS parts of all sorts still continue to turn up.

The manufacture of a large quantity of pattern 16H valve guides in the 70s is, I think, most unlikely..British bikes were 'dead in the water' at that time. The 'restoration scene' was not there in the early 70's and the bikes had virtually no value..By the later 70's the 'Classic' boom was only just getting underway..If there are any pattern guides they would be of much later manufacture I would have thought...and that in itself doesn't mean that any patterns made were defective, that is not automatically the case.

Perhaps Rik can shed some light on where he obtained the parts and whether it was a dealer who generally deals in NOS?...It does seem strange as well that only Rik appears to have been a purchaser of any of these poor quality 'pattern' guides over the years...

If the guides were proven to be pattern ones of unknown quality, then the problem now is where to obtain actual NOS parts or good quality replicas. However,if Rik is pretty confident they were genuine NOS then that reason for the failure takes a major knock and another cause will have to be identified...Alpha bearings make valve guides...do they have any? The M20 ones I have had from them in the past performed as expected....Ian

email (option): ian@wright52.plus.com

I've just checked on there website and they do.

http://www.alpha-bearings.com/Valve%20cat/norton.htm

Mine came from Russell's, only my inlet guide needs replacing, but I'm worried about changing it now.

email (option): horror@blueyonder.co.uk

Hi Horror..Are your guides from Russells NOS or pattern? You could get back to them to determine which one and if pattern where they came from. You may be worrying unnecessarily...and it appears Alpha are available for a 'plan B' if you don't get the right answers from Russells.

Then I guess it's just a case of fitting it, applying a .003"-.004" clearance and giving it a go..

You can't put off the inevitable!

..Ian

..Ian

email (option): ian@wright52.plus.com

Thanks for all your comments on this. My bloody 'ead's in a whirl.

I like the idea of the plasma-coated G&S Valves but there is some appeal in having valves and guides from the same source (Alpha ?)

I think that I'll have to phone Alpha, G&S and Russells next week to see if they can shed any light on what's available (and recommend some clearances).

I'm sorry to read that the same problem occurred.

Have been studying the pictures that Rik uploaded (the overheated blue silencer) and the pair of worn valve guides, and I just can't keep myself from asking the experts of this forum: could it be improper use of the magneto lever? Retard ignition can cause overheating and that explains both the blue silencer and the worn of the guides!

Just a thought...

Hi Rik, Yes that does make sense if it all comes from the same source. I think in your position that's what I'd do. But the questions I'd ask Alpha are, what are your guides made of, and what are the valves made of, and hopefully the answers will fall in line with what we've learnt.

email (option): horror@blueyonder.co.uk

Kostas. I'm quite sure Rik's timing was correct and he knows better than to run with retarded ignition. The bluing of the exhaust is a result of the guide wear which has resulted in the fuel mixture becoming altered amongst other problems. Ron

email (option): ronpier@talk21.com

I don't feel it is necessary for the parts to be sourced from the same place...G&S are a quality valve manufacturer who have produced a valve that is specifically made to run in iron guides using modern materials and methods. Alpha, with their history and line of work are likely to be producing iron guides of the right specification...I have certainly had no issues with them. There is no logical reason to suppose that 'mixing' components from quality suppliers will cause any problems and G&S are probably offering the best valve available...Ian

email (option): ian@wright52.plus.com